vip@litongglass.com

+86 16632961602

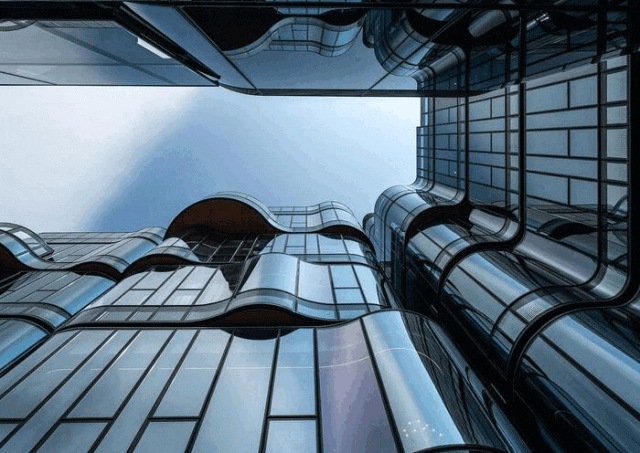

With the rapid development of glass production and further processing technology

The application of decorative glass in the field of architecture has ushered in a new revolution

The use of decorative glass has broken through the limitations of the past

We also pursue functional materials that are translucent or semi-translucent

It has developed into a comprehensive decorative material integrating color, texture, light and shadow effects

The following is a detailed introduction to the common decorative glass processing technology.

01. Patterned glass

Patterned glass is a glass that is pressed with a pattern by a pressure roller during molding

It transmits light without see-through, the light is soft, and it is highly decorative

There are various patterns such as checkered patterns and water ripples

Its main role is to meet the needs of daylighting while protecting privacy

It also adds an artistic aesthetic to a space

It is often used in doors and windows, partitions, bathrooms and other building parts

It is also suitable for commercial display areas

The size of the regular large slab of the patterned glass

It is often 1800x2440mm

1830x2134mm

1830x2440mm

The pattern of the patterned glass also has a variety of "options"

From simple geometric lines to intricate natural textures and abstract art graphics

Meet different decorative needs and aesthetic preferences

Small wick embossed glass

Patterned glass

02. Frosted glass

The frosted glass surface has a delicate frosted texture

Transparent light but not see-through

It can effectively protect privacy, soften the light and avoid glare

Create a cosy atmosphere that is both functional and decorative

It is widely used in home bathroom doors and windows, commercial office partitions and other scenarios

Add a hazy aesthetic and a sense of privacy to a space

Glass frosted glass was originally for

Protect privacy and avoid glare while ensuring light transmission

When the surface of the glass is processed into a frosted texture by mechanical grinding, chemical etching and other processes

Both blur the line of sight to prevent prying eyes

and it can make the light soft and diffuse,

Avoid visual discomfort caused by sharp reflections

There are various types of original films suitable for frosted glass

Such as ordinary float glass, strengthened tempered glass, etc

At the same time, it can also be superimposed with color coating, pattern printing, etc. through special processes

Meet different functional needs and decoration styles

It is widely used in home and commercial space

(Sandblasting and oil sand↑)

03. Bent steel glass

Bending steel glass is the process of heating the glass to the point of softening

Curved tempered glass made by mold shaping and rapid cooling

It is strong, safe and can withstand temperature differences

It can also realize sound insulation, heat insulation and other functions through the composite process

Widely used in buildings (such as curved curtain walls) and home (such as curved doors and windows)

Meet a variety of design and practical needs

04. stained glass

Tinted glass is the addition of colorants such as metal oxides to the glass raw material

Stained glass melted at high temperatures

For example, cobalt oxide makes it blue, and copper oxide makes it green

Tinted glass is beautiful and unique, rich in color, which can enhance the artistic sense of the space

It can adjust the light, soften the light, and reduce glare

It has thermal insulation performance and reduces energy consumption; Protect privacy by adjusting transparency

And it has high strength, good stability, not easy to fade and deform, and has a long service life

05. toughened glass

Tempered glass is

In addition to laminated glass, another type of safety glass

The physical tempering

of glass usually refers to heating ordinary annealed glass

to a certain temperature (usually 650-700°C).

Quenching is performed when the glass is close to softening

A compressive stress layer is formed on the surface of the glass

to improve the mechanical strength and thermal shock strength of glass

In addition to this, there is also a way of chemical toughening (also known as ion exchange tempering) for glass

Exploits the migration and diffusion of ions on the glass surface

By way of ion exchange

Compositional changes occur in the thinner glass surface layer area

This increases the compressive stress on the glass surface

The strength of tempered glass is more than 4 times that of ordinary annealed glass

Its flexural and impact strength has also been significantly improved

However, due to the uniform compressive stress on the outer surface of the tempered glass

There is a corresponding tensile stress inside

Once tempered, it cannot do any cutting, grinding and other processing

Otherwise, it will be fragmented due to the disruption of the uniform compressive stress balance

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China