Abstract:This paper summarizes the mechanical properties, failure forms and self-exposure mechanism of tempered glass in architectural glass, as well as the methods to reduce the self-exposure of tempered glass, which has guiding significance for the design and application of architectural glass.

Keywords: architectural glass mechanical properties failure form tempered glass self-exposure

1 Introduction

Architectural glass is a typically brittle material, and an in-depth understanding of its mechanical properties is important for proper design and construction. In this paper, the mechanical properties of architectural glass are reviewed, which can play a beneficial role in the application of architectural glass.

2 Mechanical properties

2.1 Elasticity

Architectural glass is a complete elastomer and no visible plastic deformation has been detected worldwide. Therefore, when designing and constructing architectural glass, its periphery should be in contact with soft materials, such as rubber strips or sealants, and should not be in direct contact with metal materials such as aluminum profiles or steel profiles.

2.2 Brittleness

There are a large number of microcracks on the surface of architectural glass, which is extremely brittle and has extremely poor fracture toughness, which is manifested as sudden fracture when it is broken. Therefore, in general, architectural glass cannot be used as an engineering structural material.

2.3 Intensity discreteness

Due to the existence of a large number of microcracks on the surface of architectural glass, its strength is closely related to the crack size, and the crack size and number exist randomly, which makes the strength of architectural glass more discrete. When designing for use, a large safety factor should be considered. In general, the safety factor when the failure probability is not greater than 0.1% should be used.

2.4 Intensity

The failure of architectural glass is closely related to the propagation of cracks on its surface, and the initial crack position, crack direction and force direction of failure determine the strength. The strength of architectural glass is divided into large surface strength, edge strength and end face strength, which should be distinguished in the design.

3 Forms of destruction

3.1 Bending Failure

Under the action of external forces such as wind load, architectural glass is manifested as the bending failure of thin plates, and the allowable strength of tempered glass is usually 84MPa, which refers to the bending strength. Architectural glass does not have compressive strength, shear strength, and tensile strength, so it makes no sense to calculate the compressive, shear, and tensile stresses of architectural glass when designing.

3.2 Impact Damage

Under the impact of the human body or objects, the architectural glass is easy to break, that is, the impact strength of the glass is low, so improving its impact strength is a key consideration in the production of architectural glass.

3.3 Thermal blasting

Under the action of temperature difference stress, architectural glass is very prone to thermal explosion. Since the initial crack of glass thermal explosion starts at the edge of the glass plate, the edge finishing has a significant effect on improving the thermal explosion resistance of the glass, and the heat treatment of the glass will also significantly improve its thermal explosion resistance.

4. Self-explosion of tempered glass

The bending strength and impact strength of architectural glass are low, and it is very easy to occur thermal explosion, which limits its application, and its heat treatment, that is, tempering treatment, can improve the bending strength of glass by 2-3 times, and increase the impact strength by 3-4 times, and there is no problem of separate thermal explosion. The excellent properties of tempered glass have greatly expanded the application of architectural glass. However, tempered glass also has obvious defects, that is, tempered glass self-explosion. Only by understanding the mechanism of tempered glass self-explosion in detail can it be correctly designed and used.

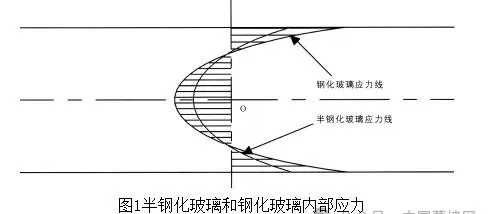

The thermodynamic tendency of the phase transition is not sufficient, and certain kinetic conditions must be present to achieve this phase transition, which in turn causes the spontaneous explosion of the glass. Flat glass is annealed glass and has no stress on its inside. Semi-tempered glass and tempered glass have internal stress after quenching, which is a prestressed material. The internal stress state of semi-tempered glass and tempered glass is shown in Figure 1.

As can be seen from Figure 1, the internal stress distribution trend of semi-tempered glass and tempered glass is the same, both the outer surface is under compressive stress and the inner is under tensile stress, the difference between the two is that the surface compressive stress and internal tensile stress of tempered glass are larger than those of semi-tempered glass.

Only the nickel sulfide particles in the glass are located in a sufficiently large tensile stress region, and the nickel sulfide particles have the kinetic conditions for phase transformation, because the phase transformation of nickel sulfide particles is accompanied by volume expansion, and a large enough tensile stress provides dynamic conditions for the volume expansion of nickel sulfide particles, which is the reason why flat glass and semi-tempered glass do not self-detonate, and tempered glass self-detonation. The nickel sulfide particles in the glass are randomly distributed, and if the nickel sulfide particles in the glass are located at the maximum tensile stress of the tempered glass, the particles may become the detonation point of the tempered glass self-explosion.

The self-explosion of tempered glass caused by nickel sulfide particles is often similar to that of butterflies at the burst point crack shape, which is called butterfly-shaped cracks, and some have a colored particle in the middle of the burst point, which is considered to be nickel sulfide particles, and these two characteristics are often used as a criterion for whether the tempered glass is self-detonating. The volume of nickel sulfide particles before and after the self-explosion of tempered glass is different, and the volume before bursting is small and not easy to be seen; After the self-explosion, its volume increases, the location is determined, and it is easy to be seen, which is one of the reasons why the self-explosion of tempered glass is not easy to predict. The self-explosion crack of tempered glass is shown in Figure 2.

The self-explosion of tempered glass caused by nickel sulfide particles is active, spontaneous, and has no external cause, which is a self-explosion in the real sense.

Two conditions are required for the self-explosion of tempered glass caused by nickel sulfide particles: first, the tensile stress of the position of the nickel sulfide particles; The size of its nickel sulfide particles. The larger the size of nickel sulfide particles, the smaller the tensile stress it needs, that is, corresponding to different tensile stresses, there is a critical size of nickel sulfide particles, the greater the tensile stress in tempered glass, the smaller the critical size of nickel sulfide particles, the more self-detonating nickel sulfide particles, the greater the probability of self-explosion of tempered glass.

In addition to nickel sulfide particles, flat glass also contains stones, bubbles and impurities, and glass is a typical brittle material, and its mechanical behavior obeys fracture mechanics. Stones, bubbles and impurities in the glass will form cracks in the glass, which is the weak point of tempered glass, especially the crack tip is the stress concentration. Stones, bubbles or impurities can cause the tempered glass to burst if they are in the tensile stress zone of the tempered glass, or if they are under tension stress under load.

China's standard requires that the surface stress should not be less than 90MPa, and the US standard stipulates that the surface compressive stress of tempered glass is greater than 69MPa. If feasible, it will greatly reduce the self-explosion rate of tempered glass. Reducing the limit of surface compressive stress value may cause the tempered glass fragment to be larger, but even if the surface compressive stress of tempered glass is very high and the fragment is very small, it is not guaranteed that the fragments exist in a split state, and in many cases the fragments are cracked but not broken, forming a "tempered glass quilt", and the result is not much different from the larger fragments, and even its harm is greater, so it can be considered to reduce the compressive stress value limit on the surface of the tempered glass. Moreover, China's semi-tempered glass standard stipulates that the surface compressive stress value limit is not more than 60MPa, and the tempered glass standard stipulates that the surface compressive stress value limit is not less than 90MPa, if the glass surface compressive stress is between 60-90MPa, it does not belong to semi-tempered glass, nor does it belong to tempered glass, and it is an unqualified product. From this point of view, the surface compressive stress value limit of the tempered glass should also be reduced, if it is difficult to connect the surface compressive stress value limit of the semi-tempered glass with the compressive stress value limit of the tempered glass surface, at least the compressive stress value limit of the tempered glass surface can be reduced to narrow the gap between the two.

In the process of processing, transportation, storage and construction, the surface and edge of the glass may cause defects such as scratches, explosions and edges, which can easily cause stress concentration and cause self-explosion of tempered glass. There are a large number of microcracks on the surface of glass, which is also the fundamental reason why the mechanical behavior of glass obeys fracture mechanics. These microcracks will propagate under certain conditions, such as the action of water vapor, the action of load, etc., which may accelerate the propagation of microcracks. Normally, the microcrack propagation rate is extremely slow, and the strength of the glass is a constant value. However, there is a critical value for microcracks on the surface of glass, and when the size of microcracks is close to or reaches a critical value, the cracks expand rapidly, resulting in glass breakage. If there are microcracks close to the critical size on the surface and edges of the glass, such as scratches, explosions, edges and other defects caused by the processing, transportation, storage and construction of the glass surface and edges, the size of the defects is large, and the glass may cause the rapid expansion of the microcracks on the surface or edges of the glass under a very small load, and eventually lead to the cracking of the glass.

To this end, the processing quality of the tempered glass edge should be improved, and the edge processing requirements should be clarified, such as complete edging on both sides or incomplete edging on three sides, so as to avoid scratches and bumps on the glass edge and surface. Theoretical analysis and experiments show that the tempered glass edge has a low degree of toughening, so the tempered glass edge should be protected. For point-supported curtain wall glass, if the glass is perforated, the hole edge must be finely ground, and it is best to achieve the degree of polishing, because the glass hole edge is the stress concentration part.

Tempered glass needs to be heated and cooled in the production process, and the uneven direction along the glass plate surface and the asymmetry along the thickness direction of the glass during heating or cooling will lead to uneven stress along the plate surface and asymmetrical stress distribution along the thickness direction, which may cause the tempered glass to explode. The stress of tempered glass is uneven along the direction of the plate surface, which can cause the glass to be in tensile stress, if this tensile stress is too large, exceeding the breaking strength of the glass, the glass will burst. The stress distribution of the glass plate along the thickness direction should be symmetrical, that is, the upper and lower surfaces are in compressive stress, and the middle is in tensile stress, and the compressive stress size, stress layer thickness and change of the upper and lower surfaces are completely symmetrical, and the ability of the glass plate to bear positive and negative wind pressure is the same. If the stress distribution of the glass plate along the thickness direction is asymmetrical, the ability of the glass plate to bear positive and negative wind pressure is not the same, the ability to bear the load on one side is stronger, and the other side is smaller, that is, the glass may be damaged under the action of small load, and in serious cases, the glass plate is deformed under the action of no load, resulting in the distortion of the curtain wall glass image.

To this end, the surface stress uniformity and symmetry along the thickness direction of the tempered glass should be improved. Especially for the tempering of low-e glass, it is necessary to pay more attention to the symmetry of the tempered glass stress along the thickness direction, because the difference in the absorption of thermal radiation on the upper and lower surfaces of low-e glass will cause the difference in the temperature of the glass plate along the thickness direction when the low-e glass is heated, and this difference will eventually lead to the asymmetry of the stress of the tempered glass along the thickness direction.

The internal stress of tempered glass is uneven, and there is a large stress gradient, which will cause self-explosion, which is manifested as the size of the fragment particles and the large gap. There are five measurement points for surface compressive stress, which are averaged. The difference limit between the maximum and minimum values of the five measurement points should be added to characterize the compressive stress uniformity on the surface of the tempered glass.

Reducing the size of the tempered glass plate can reduce the self-explosion rate of the tempered glass. At present, China is showing a trend of larger and larger plate surface in the application of architectural glass, the larger the size of the tempered glass, the thicker the glass plate, and the greater the probability of self-explosion. In a tempered glass plate, as long as there is a self-explosion point, and eventually leads to the tempered glass self-explosion, no matter the size of the tempered glass plate, the entire tempered glass plate will be broken. The larger the glass plate, the unfavorable factors such as impurities, nickel sulfide particles, edge processing defects, surface scratches, uneven stress, etc., which lead to the self-explosion of tempered glass. Under the same load, the larger the glass plate, the thicker the glass plate, containing impurities, nickel sulfide particles, edge processing defects, surface scratches, uneven stress, etc., resulting in the unfavorable factors of tempered glass self-explosion will also increase, and the probability of tempered glass self-explosion will increase. Therefore, the size of the tempered glass plate should be limited according to the thickness and quality grade of the flat glass.

5 Concluding remarks

"Tempered Glass for Building Doors, Windows and Curtain Walls" JG/T455 and "Technical Regulations for the Application of Architectural Glass" JGJ113 make clear provisions on the production of tempered glass and the application of architectural glass.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China