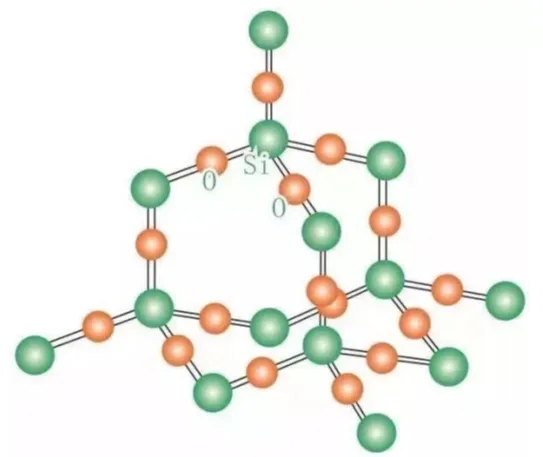

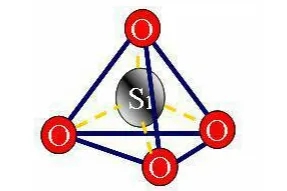

Quartz glass is a kind of special industrial technical glass composed of a single component of high-purity silica (SiO), which is generally divided into natural quartz glass (Natural Fused Quartz) and synthetic fused silica glass (Synthetic Fused Silica). Natural quartz glass is also known as ordinary quartz glass, and synthetic quartz glass is called high-purity quartz glass. The application field of quartz glass is extremely wide, there are many manufacturers at home and abroad, and the grades launched are more complex, which leads to the fact that in practical applications, users often lack the awareness of various grades of materials, so they fall into the dilemma of not knowing how to choose, so we have studied quartz glass, in view of the limited space, here only its relevant standards and grades are introduced, hoping to provide useful reference and guidance for subsequent work applications.

1.Standard

The domestic quartz glass adopts the building materials industry standard JC/T 185, which has undergone three versions in 1981, 1996 and 2013. Among them, the 81st edition divides quartz glass into far-ultraviolet optical quartz glass (JGS1), ultraviolet optical quartz glass (JGS2) and infrared optical quartz glass (JGS3) according to its application spectrum band; The 96 edition divides it into far-ultraviolet optical quartz glass (ZS-1), ultraviolet optical quartz glass (ZS-2), visible optical quartz glass (KS) and infrared optical quartz glass (HS); The 2013 edition divides it into ultraviolet optical quartz glass (ZS), visible optical quartz glass (KS) and infrared optical quartz glass (HS).

When exploring the relevant foreign standards, although we did not directly find a standard specifically for quartz glass, the standards in the field of optical glass have provided us with a certain reference, including "MIL-G-174B Military Specification Glass, military specification for optical optical glass" and "ISO 12123 Optics and photonics — Specification of raw optical". Glass Optics and Photonics - Specification for Optical Glass Raw Materials" has made detailed provisions on the key indicators such as optical uniformity and fringes of optical glass, and these standards can also provide reference for the quality evaluation of quartz glass to a certain extent.

2.Manufacturer and grade

Before the introduction, we will briefly explain the influence of hydroxyl on the spectral curve of quartz glass: hydroxyl is a key defect in quartz glass, from the spectral curve, the hydroxyl content mainly affects its transmittance, high hydroxyl content will lead to a strong absorption peak at 2.73μm in the infrared spectrum, the higher the hydroxyl content, the lower the transmittance of the absorption peak.

Quartz glass has a wide range of applications, and in this article we will only introduce optical quartz glass manufacturers and grades.

3.Domestic manufacturers and grades

Domestic manufacturers mainly include Philip, CNBM Jingrand Quartz, Changfei Quartz, Shenguang Optics, Hengxin Quartz, Zhongtian Nantong Crystal, Jinzhou Haipu New Materials, etc.

Philip Optical Quartz Glass is divided into five categories: Low Expansion Quartz (LEQZ), Low Hydroxyl Quartz (F-HDUR), Hydrous Synthetic Quartz (F-HUV), Anhydrous Synthetic Quartz (F-HIR) and Chlorine-Free Synthetic Quartz (FNCL). Among them, F-HUV has good optical performance and is suitable for high-end optical fields; F-HIR has a very low hydroxyl content and performs well in infrared laser systems; FNCL is ideal for UV applications due to its high transmittance and radiation resistance.

CNBM Golden Grant Optical Quartz Glass covers four series: JC-Z, JC-H, JC-K01 and JC-WS, JC-Z series has the characteristics of low metal impurity content and high transmittance, and is widely used in the ultraviolet band; JC-H series has metal impurities, low hydroxyl content, and can be used as optical materials in ultraviolet, visible and infrared; JC-K01 series quartz glass is widely used in the visible light band; JC-WS series quartz glass has low hydroxyl content and can be applied to visible, near-infrared and other aspects.

According to its characteristics, YOFC quartz glass is divided into zero expansion, ultra-low hydroxyl, low hydroxyxyl, high hydroxyl and deep ultraviolet optics. For industrial laser applications, YS-330L, YS-330 or YS-320 models are recommended; In the field of high power laser application, it is recommended to choose YS-2330 or YS-1320 models.

SGG Quartz Glass does not provide specific grade identification, but it is suitable for applications in the field of general precision optics.

Hengxin optical quartz glass is divided into three grades according to the preparation method and hydroxyl content: HOSQ-01, HOSQ-02 (of which HOSQ-021 is against JGS1, HOSQ-022 is against Corning 7980), and HOSQ-03 (against Corning 7979). The above information is based on the technical staff of Hengxin, and its accuracy is subject to subsequent verification.

Zhongtian Nantong crystal optical quartz glass has six grades: ZTSQ-01, ZTSQ-02, ZTSQ-03, ZTSQ-04, NTCM-01 and NTCM-03. Among them, NTCM-01 is suitable for ArF (193nm) applications, NTCM-03 is suitable for KrF (248nm) applications, ZTSQ-01 is a common UV application grade, ZTSQ-02 is suitable for medium and low power applications, ZTSQ-03 is benchmarked against Corning 7980, and ZTSQ-04 is benchmarked against Corning 7979. The above information comes from Nantong crystal technicians, and its accuracy has yet to be verified later.

There are two grades of optical quartz glass produced by Jinzhou Haipu New Materials Co., Ltd., namely HP3001 and HP3003, which correspond to JGS1 and JGS3 in the industry standard respectively.

4.Foreign manufacturers and grades

Foreign manufacturers mainly include Corning, Heraeus, Nikon, OHARA and TOSOH.

Corning Optical Quartz Glass is known as High Purity Fused Silica (HPFS), which is commonly known as fused silica in the industry. It currently has three main grades: Corning HPFS 7979, 7980 and 8655. The 7979 is designed for infrared applications; 8655 is suitable for applications in the field of deep ultraviolet; The 7980 covers a variety of specifications such as standard, KrF (248nm), ArF (193nm), mirror, and industrial grade. The metal impurity content and hydroxyl content of 8655 are lower than those of the ArF grade in 7980, and the internal transmittance at 193nm wavelength is also higher than that of the 7980 ArF grade. The Corning 7980 0F that we come into contact with in our daily work, where "0" represents the package grade and "F" stands for the optical uniformity grade.

5.Commonly used grades for optical applications

There are more than a dozen grades of Heraeus optical quartz glass, and here is an introduction to the commonly used grades for optical applications:

The Suprasil 300 series consists of Suprasil 3001, 3002 and 300, which feature ultra-low metal impurities (<1 ppm), low hydroxyl content (<1 ppm), and inherent chlorine content of 1000 to 3000 ppm, with no absorption from the visible to infrared band. With this property, these materials are the first choice for any low-absorption application in the near-infrared band.

Suprasil 311, 312 and 313 Suprasil 31X is produced in a similar way to the Suprasil 300 series, with a lower metal impurity content, no chlorine and less hydroxyl content than the Suprasil 300 series. Suprasil 31X typically has a hydroxyl content of less than 250 ppm, making it unsuitable for applications with a spectral range close to the hydroxyl absorption band, and is very cost-effective in applications with a spectral range slightly further away from the hydroxyl absorption band.

Suprasil 1 and 2 (Class A and B) have excellent physical properties and outstanding optical properties in the deep UV and visible wavelength ranges, as well as excellent resistance to radiation damage from high-energy UV lasers. Suprasil 1Arf/KrF, Suprasil 2ArF/KrF, and Suprasil UVL products are doped with H2 to reduce absorption under UV exposure.

Nikon optical quartz glass (NIFS) has four grades, namely NIFS-V, A, U, S, of which V, A, and U are for ultraviolet applications, V laser has the highest durability, and S is the standard grade, which is suitable for ordinary ultraviolet and visible applications.

OHARA optical quartz glass includes SK-1300, 1310 and 1320 series. SK-1300: Basic model for most optical and semiconductor applications. SK-1310 further reduces the hydroxyl content to less than 1ppm and improves infrared transmission performance. The SK-1320 series optimizes the laser damage threshold and is suitable for high-power laser scenarios.

TOSOH optical quartz glasses include ES series and ED-H, ES series can be used for ultraviolet (KrF and ArF) and general optical applications. With a hydroxyl content of less than 100 ppm, ED-H exhibits excellent transmission characteristics in deep UV, making it the material of choice for deep UV applications down to 170 nm.

The above content is a summary and refinement of my relevant knowledge after studying the relevant standards, literature, papers and browsing the official websites of major quartz glass manufacturers. I hereby share and look forward to learning and in-depth discussions with you. If there are omissions or inaccuracies in the content, we hope that you will give us advice and criticize and correct them.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China