5.hot melt glass

1. Features and specifications

Flat glass is used as the substrate, heated to the softening point (about 700 °C) and then molded, supplemented by inorganic pigments to achieve a three-dimensional relief effect;

2. Analysis of advantages and disadvantages

Advantages: strong three-dimensional sense of pattern, excellent decoration (such as antique relief, abstract texture); Complex shapes (curved surfaces, hollows) can be customized, and the weather resistance is good (-30°C~150°C).

Disadvantages: high cost, large weight (thick plate ≥ 30kg/㎡) installation needs to be reinforced;

3. Fields of application

TV background wall, entrance screen, art partition; hotel lobby relief wall, exhibition hall art installation;

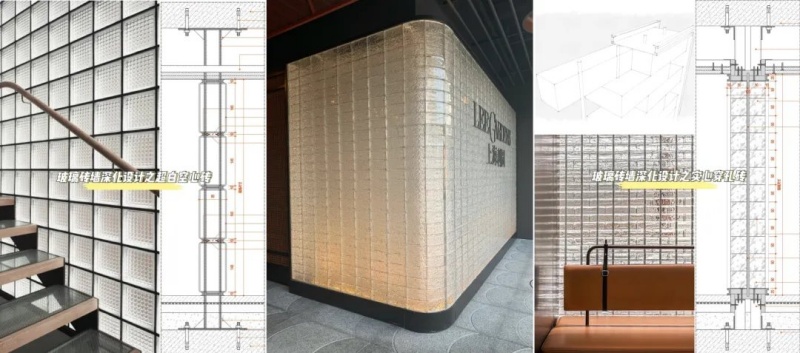

6. Glass bricks

1. Features and specifications

It is divided into two categories: solid and hollow, hollow bricks account for 90%, and the thickness of the internal airtight air layer is 80~100mm;

Standard bricks: 190× 190×80, 145× 145×80;

Large size bricks: 240×240×80, 300×300×100;

2. Analysis of advantages and disadvantages

Advantages: opaque light transmission (haze > 90%), excellent privacy; Energy-saving, thermal insulation, strong load-bearing;

Disadvantages: It cannot be cut, and it needs to be accurately typeset and designed; The cost of masonry is high (about 300 yuan/㎡ for labor + auxiliary materials).

Restricted wall height (4m after reinforcement ≤)

3. Fields of application

partition walls, dark bathroom lighting walls (such as shower areas), entrance screens, open kitchen partitions;

Exterior windows: replace traditional windows, resist wind pressure and heat insulation;

7. Mirror glass

1. Features and specifications

After polishing, the flat glass is silver-plated/aluminum-plated, which is divided into single-sided polishing (light transmittance 84%) and double-sided polishing; Thickness: 4~8mm (commonly used)

2. Analysis of advantages and disadvantages

Advantages: reflectivity > 90%, expanding the sense of space; Can be reprocessed; Compatible with safe handling (toughenable).

Disadvantages: easy oxidation of the plating, high installation requirements, ghosting problems (double-sided mirrors affect vision).

3. Fields of application

Mirror wall of dance room, fitting room of shopping mall, elevator car, wardrobe door, bathroom mirror cabinet (anti-fog treatment) art collage mirror;

8. Wire glass

1. Features and specifications

The surface can be embossed or polished, and the wire mesh can be customized with diamond-shaped, square and other patterns to enhance the aesthetic effect;

Thickness 4-10mm (commonly used)

2. Analysis of advantages and disadvantages

Advantages: Support the customization of colored glass substrate and wire pattern to meet the needs of modern design;

Disadvantages: The cutting edge metal wire is easy to oxidize and rust ("rust cracking" phenomenon), resulting in self-cracking of the glass, and it is necessary to apply anti-rust coating or edge banding;

Process limitations, production is prone to bubbles, rust spots, and the rate of high-quality products is low; Composite sandwich is required to improve safety;

3. Fields of application

Artistic partitions, stair railings, custom furniture (e.g. embossed glass coffee tables)

Commercial spaces (exhibition halls, hotel lobbies) translucent screens, combined with lighting to create an atmosphere;

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China