Laminated U-shaped glass is an architectural glass material with unique structure and performance, which combines the mechanical advantages of U-shaped glass with the safety characteristics of laminated glass, and shows many advantages in the field of construction, as follows:

Superior mechanical properties

High strength and stiffness: The U-shaped structure itself has good bending and wind pressure resistance, and the sandwich design further enhances the overall rigidity, which can withstand large loads, and is suitable for large spans or load-bearing building parts (such as curtain walls, skylights, etc.).

Resistance to deformation: The laminated structure can reduce the deformation of the glass due to temperature changes or external forces, avoid cracking caused by bending or twisting, and prolong the service life.

Security stands out

Impact & Explosion Resistance: PVB (Polyvinyl Butyral) or other film layers in the middle of the laminate can bond broken glass fragments together, and even if it is cracked by impact, it will not produce splashing glass slag, reducing safety hazards and meeting building safety standards.

Anti-theft and anti-vandalism: The laminated structure increases the difficulty of glass destruction, improves the anti-theft performance of the building, and is suitable for places with high security requirements (such as banks, commercial buildings, etc.).

Good optical and energy-saving effects

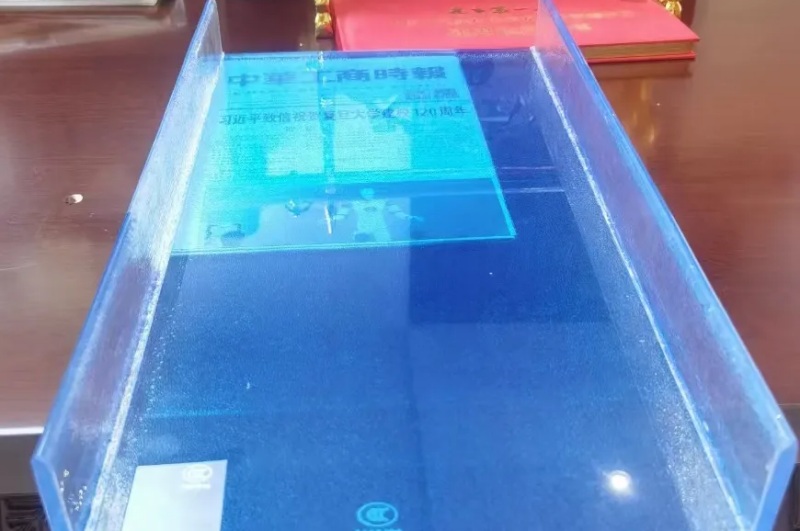

Light transmission uniformity: The U-shaped structure can evenly distribute the light and reduce glare, while the sandwich design does not affect the overall light transmittance, which can create a soft indoor light environment.

Thermal insulation: The air layer or film layer in the interlayer can reduce the heat transfer coefficient (K value), reduce indoor and outdoor heat exchange, and cooperate with technologies such as Low-E coating to achieve more significant energy savings, which helps buildings achieve green and energy-saving standards.

Sound insulation and noise reduction: The sandwich structure has a good blocking effect on sound waves, especially the attenuation effect of medium and high frequency noise, and can be used in buildings in noise-sensitive areas such as airports and railways.

Flexible in decoration and styling

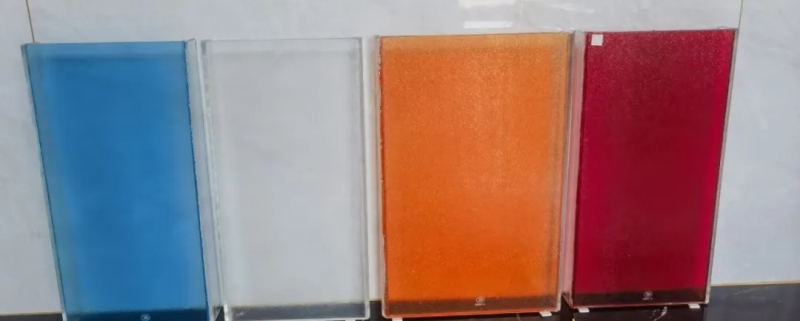

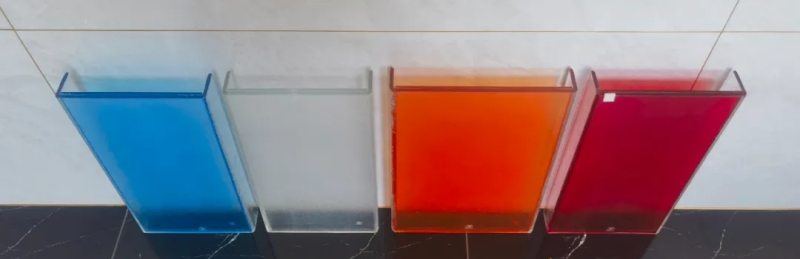

Unique architectural aesthetics: The three-dimensional structure of U-shaped glass can form a unique light and shadow effect, and the sandwich design can be matched with color film, frosted glass, etc., to meet the needs of personalized decoration, and is often used in the façade design of modern buildings.

Styling diversity: Laminated U-shaped glass with different arcs and sizes can be customized according to the needs of architectural design, adapting to complex shapes such as curved surfaces and broken lines, and expanding the possibilities of architectural design.

Easy to install and maintain

High construction efficiency: The modular design of the U-shaped glass is easy to install, and the sandwich structure reduces the risk of breakage during transportation and installation, and shortens the construction period.

Low maintenance cost: The laminated glass surface is not easy to be polluted, and the structure is stable, so there is no need for frequent maintenance in long-term use, reducing the later operating cost.

Wide range of application scenarios

Building curtain wall: both beautiful and safe, suitable for high-rise office buildings, commercial complexes, etc.

Roofs and skylights: resistant to wind pressure and falls, while providing sufficient light.

Partitions and screens: sound insulation and light transmission create a private and transparent indoor space.

Special buildings: such as museums, exhibition halls and other places with high requirements for safety and lighting.

1. Preparation of original glass sheets

High-quality quartz sand, soda ash, limestone and other raw materials are selected, mixed in a specific proportion and put into the melting furnace, and melted into molten glass at a high temperature of 1500-1600 °C.

And the edge is edging to prevent stress concentration.

2. Preparation of sandwich material

Commonly used sandwich films are PVB (polyvinyl butyral), SGP (ionic interlayer) or EVA (ethylene-vinyl acetate), typically 0.38-1.52mm thick.

The film should be stored in a constant temperature and humidity environment (20-25°C, humidity ≤30%) for 24 hours in advance to avoid moisture affecting the adhesion.

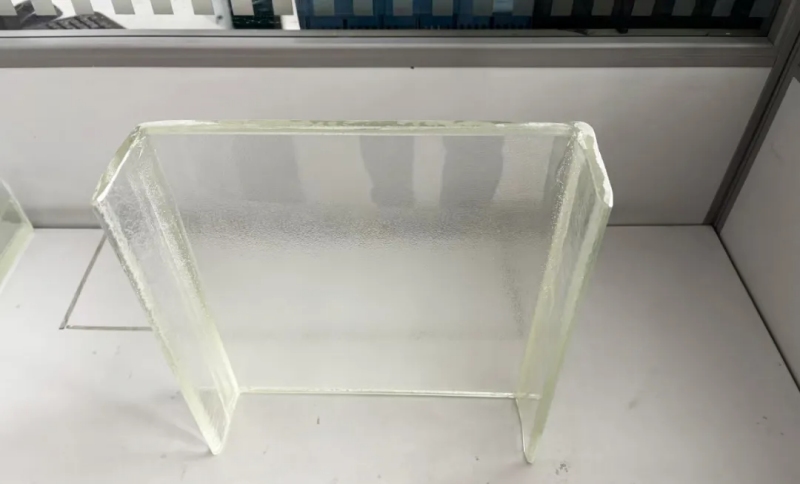

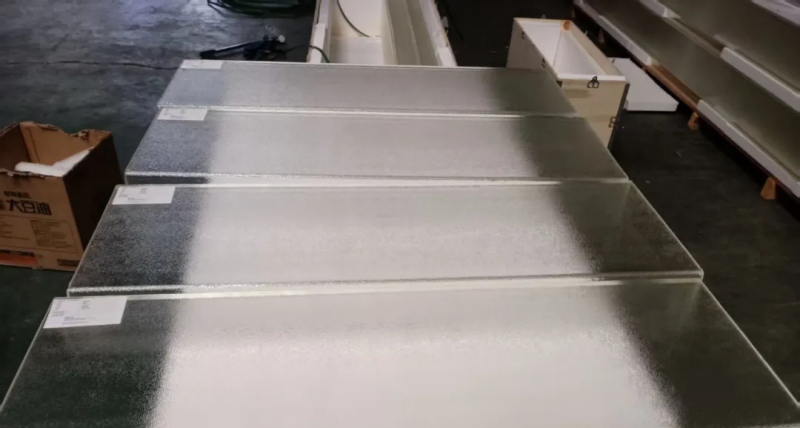

3. U-shaped glass forming process, U-shaped glass forming is the use of calendering method (efficient process):

After the molten glass is rolled into shape, it is pressed into a U-shaped glass mold, and then enters the annealing kiln (temperature 600-650°C) to slowly cool to eliminate internal stress, and the annealing time is usually 2-4 hours.

4. Sandwich composite treatment

a. Glass cleaning and drying

Clean the inner and outer surfaces of the U-shaped glass with deionized water and neutral detergent to remove impurities such as oil and dust, and then dry it with hot air (at a temperature ≤ 60°C) to ensure that there is no moisture residue on the surface.

b. Film laying and lamination

Place the U-shaped glass horizontally on the clean workbench and cut the film according to the size of the U-shaped groove so that the film completely covers the inner surface of the glass (5-10mm margin is reserved for the edge). Make sure the film fits snugly to the glass to avoid air bubbles.

c. Pre-pressurized exhaust

The laminated U-shaped glass is placed into a pre-pressing device (such as a vacuum bag or roller press), heated to 60-80°C at a vacuum of 0.05-0.08MPa, and held for 10-15 minutes to expel the air between the film and the glass to form a preliminary bond.

d. Autoclave compounding

The pre-pressed glass is placed in an autoclave and held at a pressure of 1.2-1.5MPa and a temperature of 130-140°C for 1-2 hours to allow the film to completely melt and bond firmly to the glass.

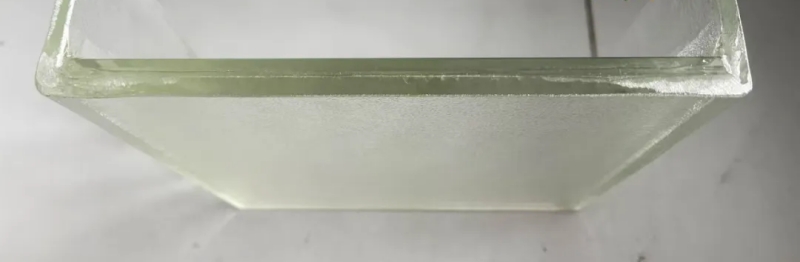

Cool to room temperature and remove and check the adhesion strength of the sandwich (peel strength ≥30N/cm) and internal bubbles (bubbles with a diameter of ≤1mm are allowed, no more than 5 per square meter).

5. Post-processing and quality inspection

Edge processing

The edges of the laminated U-shaped glass are re-edging or sealed to prevent moisture from penetrating into the laminate and prolong the service life.

Performance testing

Mechanical properties: test wind pressure resistance (need to meet GB/T 21086 standard), flexural strength (deformation under load≤ 1/200 of the span).

Safety performance: impact test (drop from a height of 1.2m with a 227g steel ball, no splashing after glass breaking), anti-theft performance (anti-pry time≥ 15 minutes).

Optical and energy-saving: Detect light transmittance (≥80%), heat transfer coefficient (K value≤ 2.5W/(㎡・K)), and sound insulation (≥30dB).

6. Special process development

Coated laminated U-shaped glass: The surface of the U-shaped glass is coated with Low-E film, sunlight control film, etc., to improve the energy saving effect, and the coating process needs to be completed before the laminated lamination.

Coloured laminated U-glass: Decorative effects are achieved using coloured PVB film or glaze printed on the surface of the glass, which is cured at high temperatures (600-700°C) after printing.

The production of laminated U-shaped glass integrates glass thermoforming and laminated composite technology, and realizes the unity of high strength, high safety and energy saving through multiple processes such as raw material control, U-shaped glass molding, laminated bonding and post-treatment. Different application scenarios (such as curtain walls, lighting roofs) can be customized by adjusting the thickness of U-shaped glass, film type and coating process to meet the needs of architectural functions and design.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China