01 Basic Flat Glass

1. Float glass

Features: smooth surface like mirror, no ripples, high light transmittance, good thickness uniformity;

Advantages: ood perspective and light transmittance, certain sound insulation and thegrmal insulation performance, high chemical stability;

Disadvantages: poor thermal stability, easy to burst;

Application: The basic material for almost all flat glass applications, and also the main original sheet for deep-processed glass (such as tempered, coated, hollow, etc.);

2. Calendered glass

Features: Produced by calendering method, the molten glass is rolled into forming by the pressure roller, and the surface is concave and convex texture or pattern due to contact with the calendering roller or calendering table;

Optical characteristics: the surface texture makes the light diffuse, transparent but opaque, and has the functions of lighting and privacy protection;

Other types: including patterned glass, corrugated glass, laminated glass, etc.;

Applications: building doors and windows (areas that require privacy) partitions, bathrooms, furniture, lamps, photovoltaic module covers (ultra-white calendering), etc.;

02 Decorative glass

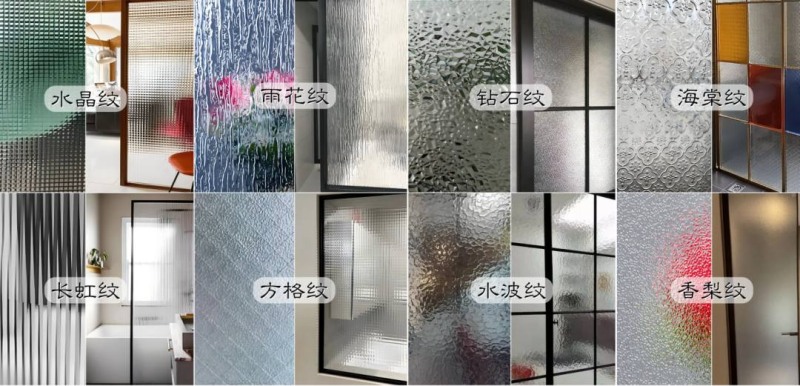

1. Embossed glass

1. Features and specifications

Before the glass hardens, the concave and convex patterns (such as geometric patterns, plant patterns, etc.) are pressed on one or both sides through the pattern roller, and the light is not see-through; Thickness: 3-12mm;

2. Analysis of advantages and disadvantages

Advantages: the light transmittance is more than 80%, but the perspective is less than 50%; Three-dimensional patterns such as stripes, diamonds, and flowers can be customized;

Disadvantages: Cleaning difficulty: the groove of the pattern is easy to accumulate dust, and it needs to be brushed regularly;

3. Fields of application

It is mainly used for space partitions (living room screens, entrances), doors and windows (toilets, shower rooms), furniture finishes (cabinet doors, desktops), and is also used in photovoltaic module covers;

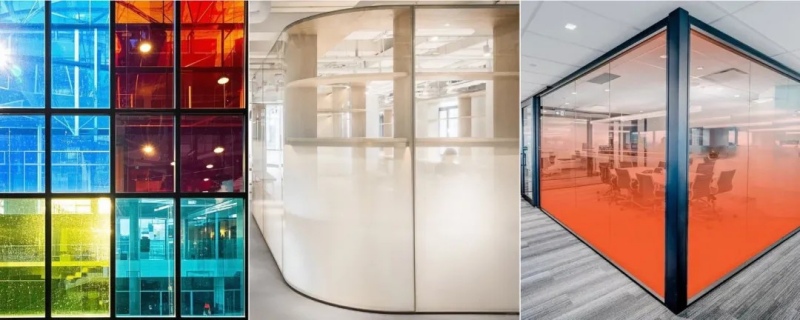

2. Stained glass

1. Features and specifications

Stained glass is made of glass as the base material, painted with special pigments and fired at low temperature (traditional process) or digital inkjet lamination (modern process); The thickness range is 3~12mm, and the maximum plate width can reach 3m×2m;

2. Analysis of advantages and disadvantages

Advantages: Rich colors and complex patterns can be personalized design; The light-transmitting decoration combined with the light can create a sense of atmosphere, and the base material is mostly tempered glass, which is not easy to hurt people after breaking;

Disadvantages: The price is higher, and the hand-painted products exceed 1,000 yuan per square meter; Digital products are susceptible to aging: UV ink may fade due to sunlight;

3. Applications

It is mainly used for religious buildings (church color windows), commercial spaces (hotel partitions, ceilings), home decoration (sliding doors, screens), modern digital painting, and furniture veneer;

3. Glazed glass

1. Characteristics and process

Glazed glass is coated with colored glaze (base glaze + metal oxide pigment) on the surface of the glass substrate, and sintered at 670~715 °C; Thickness: 4~19mm;

2. Analysis of advantages and disadvantages

Advantages: rich color, cadmium red, cobalt blue and other inorganic pigments have a wide color gamut; Easy to clean and maintain: the glaze is smooth and stain-resistant;

Disadvantages: non-temperable (part of the process); Curved surface installation is easy to burst;

3. Applications

It is mainly used for building curtain walls, sunshade components, logo background walls, and also used for stove panels and furniture finishes;

4. Frosted/sandblasted glass

1. Characteristics and processes

Frosted glass is ground by sandblasting (emery impact) or dissolved with hydrofluoric acid to form a fine concave and convex layer on the surface. Its core function is to soften glare without see-through (diffuse reflection of light). The thickness is mostly 3~8mm, and the haze value is >90%;

2. Analysis of advantages and disadvantages

Advantages: privacy protection, light transmittance of more than 85%, perspective of less than 30%; The strength is slightly higher than that of ordinary glass, and the price is lower than that of embossed glass;

Disadvantages: non-cut: custom size required; When the temperature difference is too large, the tempered frosted glass may burst (the probability is about 0.3%)

3. Applications

It is widely used in doors and windows (toilets, offices) partitions, and experimental utensils (gas collection cylinders) when installed, and the rough surface should be facing the line of sight blocking side (such as the bathroom with the rough surface facing outward)

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China