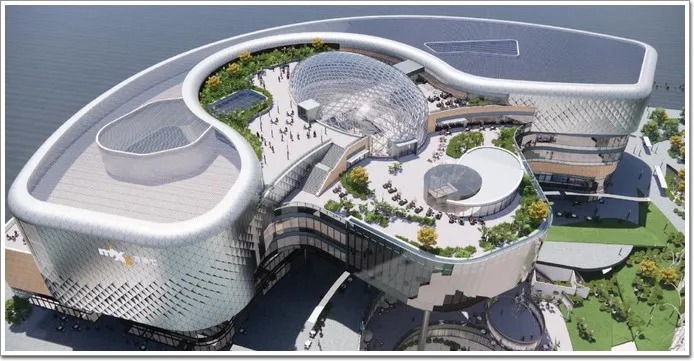

To realize this grand vision, the project team has successfully overcome the challenges of the intersection of architectural aesthetics, structural engineering and functional realization with the excellent concept of "integrated design" as the core, and presented a fusion of art and technology to the world.

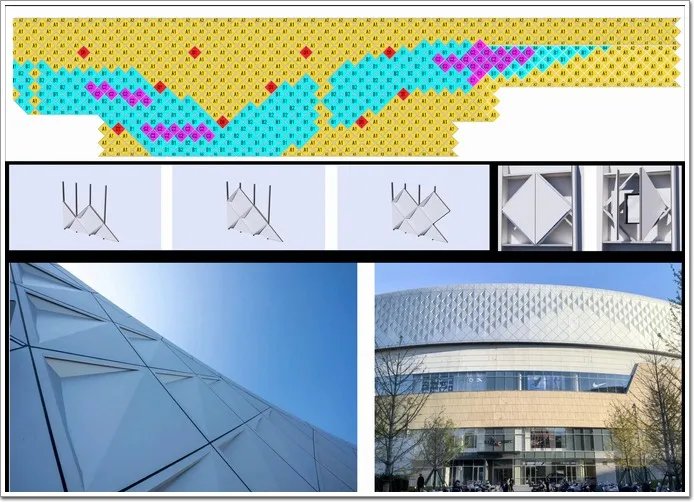

"Dragon scale" curtain wall details and real-life photos

The building's façade design is unique, and the visually striking "dragon scale" aluminum panel curtain wall system has become its iconic aesthetic feature. This curtain wall is not a simple skin, but a clever combination of three shapes of aluminum panels: flat plate, 150mm groove and 300mm groove.

In order to outline the magnificent arc of the building, the design team used up to 28 polyline panels at different angles for fitting. Each diamond-shaped aluminum plate needs to be precision machined and fixed to the prefabricated keel by plugging in, which shows the exquisite craftsmanship. What's even more commendable is that this highly artistic complex shape perfectly balances practical functions, cleverly integrating necessary facilities such as opening smoke exhaust windows and fire rescue windows into the texture of "dragon scales".

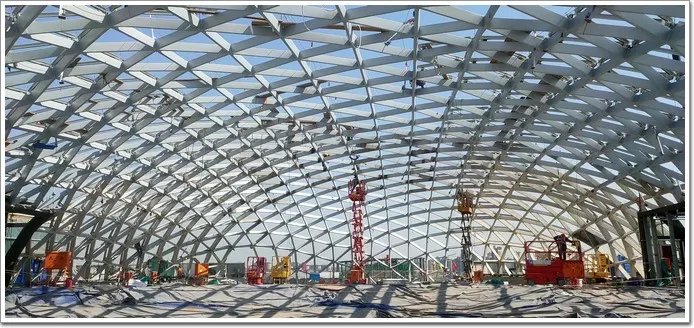

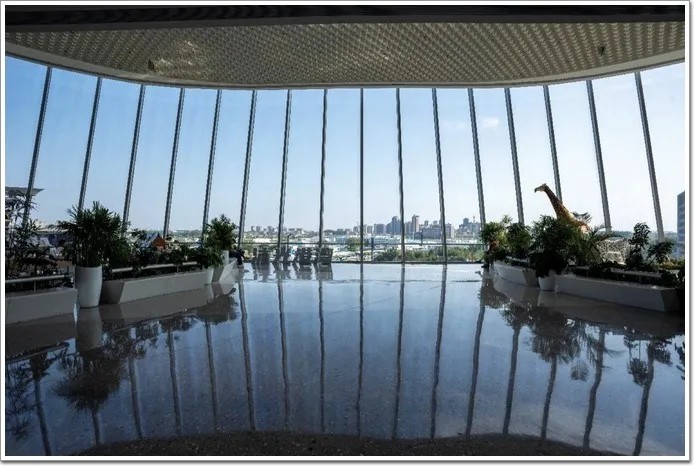

This huge ellipsoidal single-layer mesh shell skylight roof has a long axis span of 53.82 meters, a short axis span of 36.55 meters, and an arch height of 8.7 meters, covering the atrium space from an altitude of 41.8 meters.

Its span of 53.82 meters has exceeded the recommendation in the "Technical Regulations for Spatial Grid Structures" that a single mesh shell should not be larger than 50 meters, making its structural accounting a major engineering challenge. The entire dome is made up of 1,073 triangular glass and aluminum plates of different sizes, introducing changing light and shadow into the interior during the day.

The project adopts an ellipsoidal three-way grid type, and the "skeleton" of the structure is precisely connected by customized 250/150-75/t10 mm isosceles trapezoidal tube section members and high-strength six-limb cast steel hub nodes. The subtlety of its design lies in the steel frame chassis 350/450/16/18mm annular box girder, which is like a giant hoop ring, as a tensile ring of the structure, absorbing and digesting the huge horizontal thrust of the arch shell, forming an efficient self-balancing force system.

To ensure the absolute safety of the giant dome, the project team carried out a rigorous analysis that went beyond the norm. Considering the defect sensitivity of the structure, the team used a full-process analysis of elastoplastic properties, which confirmed that the overall stability of the structure is the main control factor, rather than the strength of the member alone. More importantly, the project's seismic fortification goal has been raised to a very high standard of "unyielding to earthquakes".

The results show that under the action of rare earthquakes, the maximum stress of the structure is 341MPa, which is lower than the yield limit of 355MPa, and the seismic fortification requirement of "large earthquake does not yield" is achieved.

At the same time, the finite element analysis of the key steel casting joints also shows that the maximum stress is 287MPa, which is lower than the yield strength of G20Mn5 steel of 300MPa. In order to effectively release temperature stress and cope with earthquakes, the entire dome ends up on a two-way sliding uplift-resistant spherical hinge bearing.

On the other side of the building, the "cantilever glass box" adds a modern touch to the façade with its transparency and lightness. This unique mass presents an outwardly inclined gradient surface with a maximum camber of 1.5 meters. To achieve this complex shape, the designer cleverly used flat glass for fitting, using a total of 120 glass panels of different sizes, some of which were 10.7 meters high. Its 10+2.28SGP+10mm Low-E+12Ar+15mm ultra-white tempered glass configuration ensures excellent permeability and energy-saving effects. To ensure accuracy, the team used Rhino software to perform sophisticated BIM modeling, generating machining data for each unique steel column, beam, and connector.

The success of Tongzhou Vientiane Hui lies not only in the artistry and engineering excellence of its design, but also in its in-depth practice of integrated design of curtain walls and support structures. These complex projects often face a "gray border" between architectural, structural and curtain wall specialties. To this end, the project management team innovatively adopted the PDCA cycle tool of the QC team, and after comparing various management solutions, decisively chose the "integrated scheme design of curtain wall and steel structure" led by the curtain wall consultant, and then reviewed by the structural consultant and the construction drawing institute, and finally the "curtain wall + steel structure" consortium was responsible for the construction. This management innovation clearly defines the responsibilities of all parties, greatly reduces the barriers of cross-professional collaboration, and lays a solid foundation for the smooth completion of the project.

Beijing's first China Resources Tongzhou Vientiane Hui has built a modern commercial landmark integrating artistry, functionality and forward-looking technology with its agile "dragon scale" curtain wall, magnificent "Canal Pearl" lighting roof and light "glass box". It is not only a masterpiece of engineering, but also a profound exploration and successful practice of future urban architecture in terms of design, technology and management mode.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China