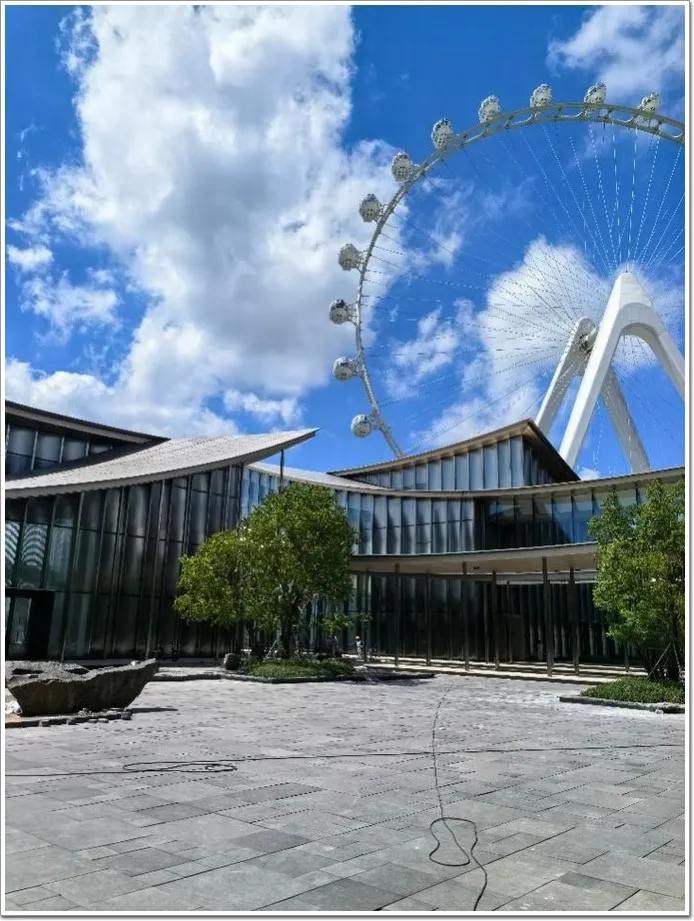

The Suzhou Museum of Contemporary Art Project, located on the right bank of Jinji Lake in Suzhou Industrial Park, is a key cultural tourism project in Suzhou. The project consists of 12 individual buildings, which are connected to each other by outdoor corridors. The project has a maximum construction area of 23.99m, a total construction area of 58,883.47 square meters, and a total curtain wall area of 65,000 square meters. The overall design of the building was completed by the internationally renowned architectural firm BIG (BjarkeIngels Group) in Denmark, and its founder BjarkeIngels personally participated in the formulation of the plan.

Zhongheng Design Group Co., Ltd. Qin Wei photography

Curtain wall design highlights

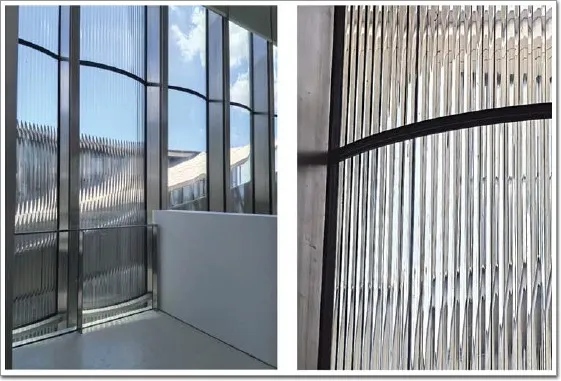

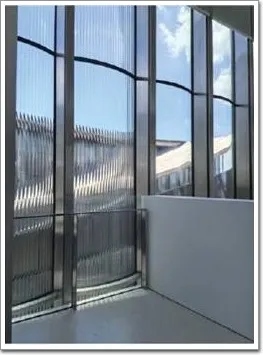

The extensive use of stainless steel materials: 68% of the total area of the project. Stainless steel has the characteristics of corrosion resistance, plasticity, not easy to damage, easy maintenance, etc., which greatly reduces the environmental impact of the product in the whole life cycle, and is conducive to minimizing the cost of the whole life cycle, and its super durability reduces the whole life cycle cost of the product by about 30% compared with similar materials.

Long-span curtain wall structure integration technology: In order to meet the lightweight needs of roof steel structure, the curtain wall is stressed by the bottom support. Due to the large slope of the cornice at the edge of the building, the height of the curtain wall columns varies from 7.5m to a maximum of 23.0m, which is very different. According to the span and civil engineering connection, the columns are sorted out into 10 types, and through reasonable force analysis, the final 8 types of column sections are used to maximize the economy and low carbon of the curtain wall.

Rigid joint design at the bottom of curtain wall columns: Make full use of the strength of stainless steel, adopt the form of rigid connection at the bottom, which is not commonly used in curtain wall design, to control the deflection of the column and reduce the cross-section of the members. Taking the 19m single-span column as an example, the weight of a single keel is reduced by 20%, which greatly improves the permeability of the curtain wall and reduces carbon emissions.

Glass vertical opposite side support technology: combined with the glass grid area and thickness configuration, the glass panel adopts opposite side support, and the curtain wall transverse keel is set up every two vertical grids, which reduces the material content of the crossbar by 50% and improves the permeability of the façade.

The use of fully welded stainless steel roofing: the "bowl" shaped roof with a concave center of the single roof of each exhibition hall puts forward extremely high requirements for roof waterproofing. The overall 450mm thick structure contains all the functions and effects of structure, waterproofing, thermal insulation, sound insulation and finishing. A light and slim visual effect is achieved.

In addition, the application of parametric design, small unit prefabrication and plug-in structure and other technologies improves the construction accuracy and system durability, reflecting a high degree of collaboration between design and construction. The project strikes a good balance between structural safety, energy conservation and environmental protection, and visual expression, providing practical experience for the design of envelope systems similar to cultural buildings, and setting a new benchmark for how contemporary architecture can achieve technology implementation in traditional meanings.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China