Glass production process - pull-down method

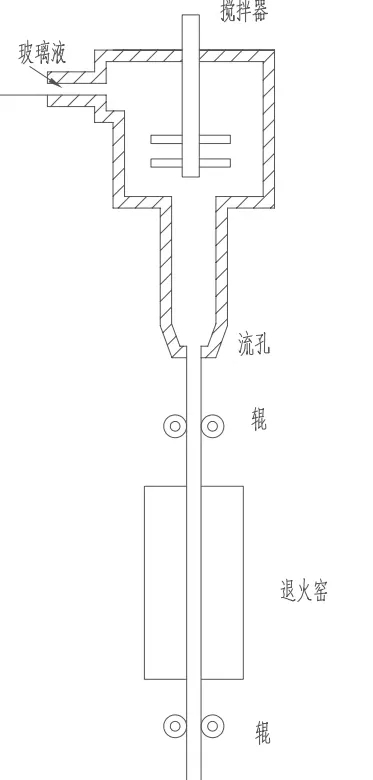

1. Flow hole pull-down method

The flow hole pull-down method uses low viscosity homogeneous glass liquid into the flow hole leak plate groove made of platinum alloy, and uses gravity and pull-down force and the size of the flow hole to control the thickness of the glass plate, in which the temperature and the size of the flow hole openings jointly determine the yield of glass, while the size of the flow hole opening and the pull-down speed jointly determine the thickness of the glass, and the temperature distribution determines the warpage of the glass.

This method mainly produces ultra-thin alkali-free flat glass for electronic information.

The production capacity of the flow hole pull-down method is 5~20t/d, and it can produce ultra-thin flat glass with a thickness of 0.03~1.1mm. In the flow hole pull-down method, precise control of the thickness of the glass plate is achieved by adjusting the process parameters, such as temperature and flow hole opening size.

This technology allows for the production of a large number of ultra-thin alkali-free flat glass of different thicknesses in a short period of time, thus meeting the diverse needs of glass materials in the field of electronic information.

Specifically, the daily production capacity can reach 5 to 20 tons, and can be flexibly adjusted to meet different market demands.

In the flow hole pull-down method, we can achieve precise control of the thickness of the glass plate by finely adjusting the process parameters, such as temperature and the size of the hole opening of the flow hole. This advanced production technology makes it possible to mass-produce ultra-thin alkali-free flat glass of varying thicknesses in a short period of time, allowing for flexible response to the diverse needs of glass materials in the field of electronic information.

In the field of electronic information, there are increasingly requirements for the thickness and performance of glass materials. Among them, 1.1 mm ultra-thin flat glass has attracted widespread attention in the market due to its lightweight and good light transmittance. However, manufacturing this ultra-thin flat glass is not an easy task and requires exquisite Imageworkmanship.

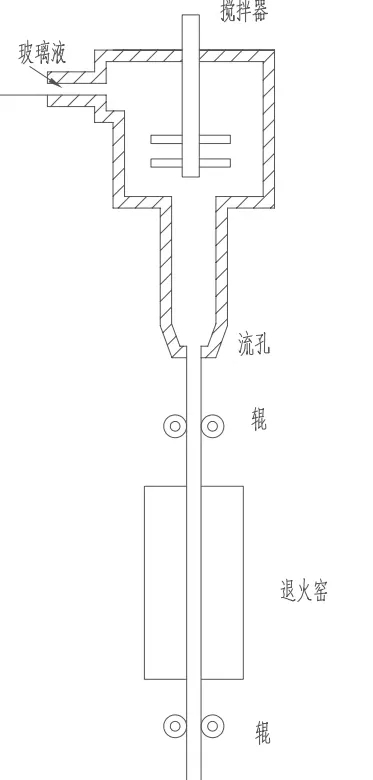

2. Overflow pull-down method

The overflow pull-down method differs from the traditional pull-down method. In this process, molten glass is introduced into a combined pipe resembling a rain gutter, after which the liquid glass overflows from the tube and re-fuses at the lower end of the tube, resulting in a continuous fabrication of slab glass.

A very flat glass surface is created because the part of the glass that comes into contact with the tube wall forms the central thick part of the glass plate, while the surface is in direct contact with the air. This process is particularly suitable for the production of ultra-thin alkali-free flat glass required in the field of electronic information.

With a daily production capacity of 5-20 tons, it can produce glass products of different thicknesses.

This method mainly produces ultra-thin alkali-free flat glass for electronic information.

The production capacity of the overflow pull-down method is 5~20t/d, which can produce ultra-thin flat glass with a thickness of 0.03~1.1mm.

The glass produced by the pull-down method is mostly used in the display and high-tech fields.