In the "protection system" of building safety, fireproof glass is like an invisible barrier, silently guarding the safety of the space. But did you know? This barrier actually has two completely different "structural ideas" - a single piece of fireproof glass is like a "hard-core lone ranger", relying on its own strength to resist risks; Composite fireproof glass is like a set of "precision combination punches", relying on multi-layer cooperation to build a solid line of defense. They have their own merits, and only by choosing the right one can the safety protection be just right.、

01. The "personality code" in the material

Behind each piece of fireproof glass, there is a unique safety grid system. They do not have a single light transmission attribute like ordinary glass, but show a completely different guardian posture at critical moments through the exquisite design of material genes. Behind this, it is the material code of the monolithic and composite fireproof glass that is quietly working.

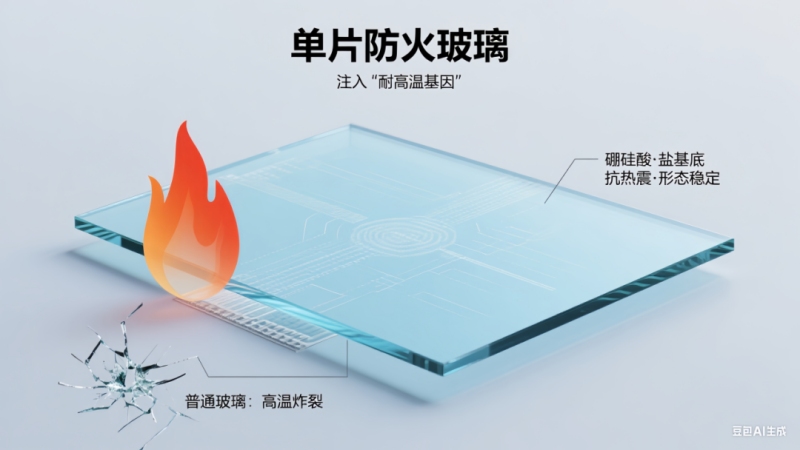

The "confidence" of a single piece of fireproof glass comes from pure materials

It is based on borosilicate or aluminosilicate glass, and by adjusting the chemical composition, it is like injecting the glass with a "high temperature tolerance gene". This material is naturally resistant to thermal shock, and when it is roasted by fire, it will not explode like ordinary glass, but can maintain a stable shape, which can be called the "calm school" of the glass industry.

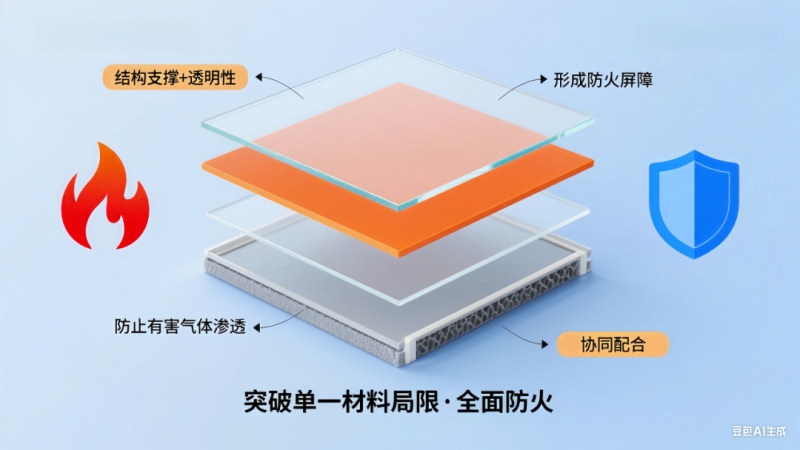

Composite fireproof glass takes the "team route"

It is completed through the synergy and division of labor of various materials such as glass sheets, fireproof adhesive layers (or fireproof fluids), flame retardant sealant strips and other materials - glass sheets provide structural support and transparency, the fireproof materials in the middle form a fire barrier in the event of a fire, sealing rubber strips prevent harmful gas penetration, and a variety of materials give full play to their own advantages and cooperate with each other to jointly achieve a comprehensive and reliable fire prevention effect, breaking through the performance limitations of a single material.

02. The "skill points" determined by the structure

The structural design of fireproof glass also directly determines their allocation of "skill points" in the dimensions of safety and practicality. It is precisely by virtue of completely different structural logic that monolithic and composite fireproof glass present a "skill tree" with its own focus on key capabilities such as light transmittance, impact resistance, and fire insulation.

01 Monolithic Fireproof Glass – "Minimalist Aesthetics"

The single glass layer allows it to transmit light, like an ultra-clear lens with little obstruction when sunlight passes through, especially suitable for places where transparency is required. And its impact resistance is outstanding, daily bumps are like tickling, installed in crowded shopping mall windows, museum display cabinets and other places, which is both safe and does not affect the aesthetics.

02 Composite fireproof glass – "multi-layer sandwich"

This superimposed design makes it highly skilled in fire and thermal insulation: the glass layer is responsible for blocking the penetration of flames, and the fireproof material focuses on cutting off heat transfer. For example, in the event of a fire, it can act like an "insulation wall", firmly locking the high temperature on one side and preventing the object on the other side from being scorched. However, this "multi-layer buff" also makes it slightly heavier, and the light transmission is slightly inferior to that of monolithic glass, and the load-bearing issue needs to be considered when installing.

03. "Multiple-choice questions" for scene adaptation

01 Monolithic fireproof glass – light and shadow coexist with safety and elegance

When the design pursues a balance of "transparency as the soul and safety as the shield" - such as the floating partition of a Michelin restaurant that needs to allow light and shadow to flow freely in the space, or the glass exhibition wall of an art museum needs to fully present the color tension of the artwork, a single piece of fireproof glass is an ideal choice. It uses borosilicate / aluminosilicate as the core of its genes, and while maintaining more than 90% of the light transmittance, it can maintain structural stability for 60-90 minutes in the face of fire, which does not destroy the visual coherence of the space, and can build the first line of defense in the early stage of the fire, especially suitable for commercial spaces with strict lighting and aesthetic requirements, and has significant cost-effective advantages.

02 Composite fireproof glass – double safety guards the passage of life

If the scene is marked with "fire prevention + thermal insulation dual needs" - for example, the fire door of the refuge floor of a super-high-rise building needs to resist flames and high temperature conduction at the same time, or the evacuation passage of a five-star hotel must block the spread of toxic fumes, and composite fireproof glass shows the advantage of team combat. Its multi-layer structure of glass sheet + fireproof adhesive material + sealing system can achieve long-term fire integrity and thermal insulation, and buy critical time for personnel evacuation, which can be called a double safety lock of the safety system.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China