Abstract: With the rapid development of China's economy, curtain wall, as an external maintenance structure, is becoming more and more different. It fully reflects the richness and diversity of curtain wall engineering. The difference between some curtain wall projects and the previous new curtain wall projects is very obvious, if the design can not fully consider the curtain wall construction technology, the use of inertial thinking for curtain wall design, will lead to difficulties in the construction of the curtain wall. Through the comparison of curtain wall design and curtain wall construction technology, this paper proposes that the necessity of construction should be fully considered in curtain wall design.

Key words: prefabricated and construction technology

Introduction: With the rapid development of China's economy, the curtain wall industry has also ushered in many changes. The types of curtain walls are becoming more and more abundant, and the construction methods and construction tools of curtain walls have also been greatly improved. The proportion of existing building renovation projects in curtain wall projects has gradually increased, and there are certain differences between some curtain wall systems and new curtain walls, and the construction methods of curtain walls have also undergone some changes. Curtain wall designers should fully consider the characteristics of the curtain wall and find a construction process that meets the characteristics of the curtain wall. Avoid the disconnection between curtain wall design and construction technology. At the same time, curtain wall designers should consider the whole life cycle of the project, including material selection, material processing, assembly, installation, use and post-maintenance work of the curtain wall. It is not only to consider individual factors such as the utilization rate of curtain wall materials, but also to fully consider the structural characteristics of the curtain wall and the construction technology of the curtain wall from the initial stage of the design scheme, and give a reasonable grasp of the whole life cycle of the curtain wall.

In actual work, sometimes encounter some special curtain wall projects, because the designer does not fully consider the curtain wall construction technology, resulting in the curtain wall project in the implementation process is very difficult. This paper intends to preliminarily discuss the necessity of considering the construction process in the design, and provide a reasonable design for the whole process of the project. The following are a list of construction processes in the form of common curtain walls.

First, several common curtain wall construction techniques

The curtain wall is the maintenance system of the building and the beautiful coat that the building wears. Curtain walls, doors and windows are all forms of façade that are often used in buildings. Curtain walls are usually constructed from the outside of the building, while doors and windows can be constructed from the inside of the building.

1. Component curtain wall construction technology

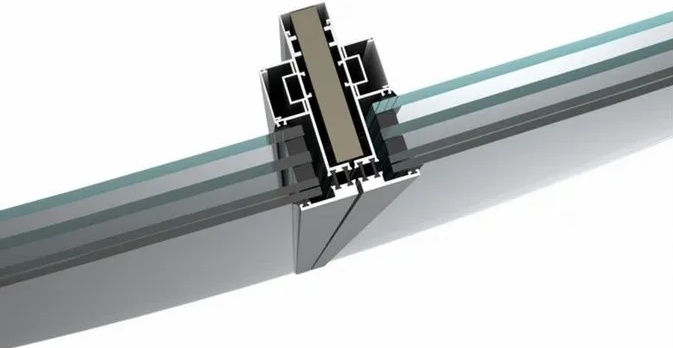

The component-type curtain wall is a curtain wall structure that is installed outside the main structure, and the vertical columns and transverse keels of the curtain wall form a grid, and then the panels and decorative lines are laid. This curtain wall structure requires construction crews to work from the outside of the building. In the early years, scaffolding was used as a construction measure for some curtain wall projects, but now most of them are constructed using hanging baskets. In recent years, more convenient construction methods such as self-elevating construction platforms have also emerged. See Figure 1 for illustration.

2 Unit curtain wall construction technology

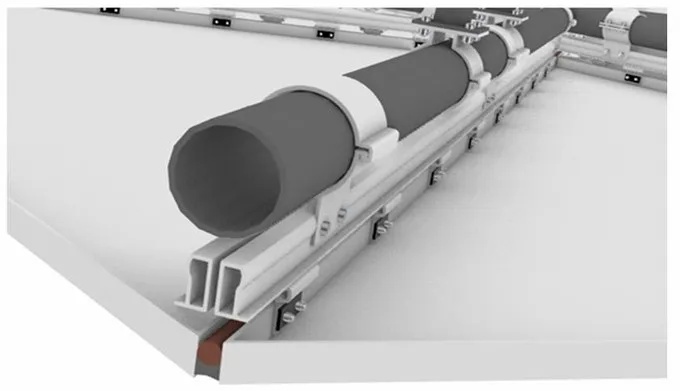

Unitized curtain wall is a form of curtain wall that is assembled in the factory and installed directly on site. The unitized curtain wall has a high degree of assembly and good assembly quality. The installation method is usually carried out by self-made lifting equipment, such as a mobile small crane, or a circular track for installation. As shown in Figure 2, the outer side of some unit-type curtain wall is provided with relatively large decorative strips or other components, which cannot be hoisted together with the unit curtain wall plate at the same time, and needs to be installed twice. At this time, it is necessary to erect a hanging basket on the roof or ring rail to place the construction personnel on the outside of the curtain wall for construction.

3 Half-unit curtain wall construction technology

A half-unit curtain wall is a form of curtain wall construction between the unit and the frame, where the main columns of the curtain wall are installed first, and then the curtain wall panels are lifted directly from the outside. The installation of curtain wall beams was eliminated, so that curtain wall construction could also be done from indoors.

4. Construction technology of metal curtain wall of suspended ceiling

The construction personnel are lifted to the corresponding position by the aerial work platform, and the construction personnel are installed from the outside, and the aerial work platform is currently very widely used, and can be constructed for many types of curtain walls, as shown in Figure 3.

Second, the development of curtain wall construction technology

With the continuous development of the curtain wall industry, the curtain wall technology is constantly updated, and there are more and more methods and means of curtain wall construction, showing the following changes.

1. There are many types of construction machinery and tools, strong capacity, all kinds of aerial work vehicles, large cranes, floor rotary cranes, ring tracks, large mobile lifting platforms and other equipment greatly facilitate the construction.

2. The labor cost of construction is getting higher and higher, and the labor cost accounts for more and more of the curtain wall cost. In the process of curtain wall construction, the dependence on construction machinery is getting higher and higher, and the efficiency of construction personnel is improved through the extensive use of construction machinery. For example, the use of power tools has become very popular, increasing the assembly speed of workers; Some circular tracks use electric brushes, which can be walked in the circular track at will, which greatly improves work efficiency.

3. The safety requirements are getting higher and higher, and the safety requirements in the curtain wall construction process are getting higher and higher. The requirements for hierarchical security control are becoming more and more detailed.

4. The construction organization requirements are becoming more and more detailed, the content of the curtain wall construction organization design is becoming more and more detailed, and many construction contents in the curtain wall construction process need to be prepared separately. When the height of the curtain wall exceeds 50 meters, it belongs to the scope of ultra-dangerous projects, and special demonstration of dangerous projects is also required.

5. There are more and more special curtain walls, and some curtain walls are no longer simply building maintenance systems with complete building functions, which are very different from curtain walls in the traditional sense. Some special curtain walls are only designed to meet the architectural requirements of shape and floodlight.

6 Curtain wall shapes are becoming more and more complex. In order to highlight the architectural characteristics, there are more and more curtain wall forms such as curved curtain wall, hyperboloid curtain wall, inclined curtain wall, and large cantilevered curtain wall.

In view of the development and change of curtain wall, the curtain wall design should also consider the influence of construction factors. It can be considered from the following aspects:

1. Curtain wall system selection: Different curtain wall systems have different requirements for curtain wall construction technology, and the appropriate curtain wall system should be selected according to the project situation. For example, the floor is not high, and the square shape of the curtain wall is suitable for the use of component curtain wall. For the curtain wall of the super high-rise regular building, the unitized curtain wall should be preferred.

2. Selection of curtain wall assembly rate: From the design consideration, we should try to choose a system with a high assembly rate, which can reduce the operation on the construction site. The processing and assembly conditions, worker quality, and product quality of the factory are obviously better than those of the site, and the processing and assembly efficiency of the factory is also significantly better than that of the site.

3. Consideration of curtain wall construction methods and construction machinery: try to use conventional construction tools and tools to reduce the use of special construction tools, for example, use hanging baskets to reduce the use of large-scale aerial work vehicles and other machinery.

4. Considering the convenience of the construction personnel, try to let the construction personnel complete the construction work in a relatively safe location, for example, the window system or the unit curtain wall system can allow the construction personnel to complete the construction work in the building room. Avoid construction personnel from being outdoors for construction work.

5. Considering the operation space of the construction personnel, there should be enough space to reserve, not too narrow.

3. The design fails to fully consider the construction situation

1. A ceiling curtain wall project

The project is a renovation project of an existing building, with a height of 60m. The top of the building is a cantilevered structure, which requires an aluminum panel and glass ceiling under the cantilevered steel structure, and a flood lighting system. Because the building itself is functionally complete, the curtain wall system is only a decorative function, and there are no performance requirements such as lighting, heat preservation, and waterproofing.

The curtain wall design adopts a conventional aluminum curtain wall and glass curtain wall structure, and the construction personnel need to lift to a height of 60m to install it from the outside, and glue and seal. Considering the difficulty of construction, the curtain wall construction organization design erects a temporary cantilever steel platform as a construction platform at a high place, and the steel platform is removed after the construction is completed. Subsequently, the aerial work platform truck is used to supplement the steel platform support structure to reserve the gap in the lower curtain wall.

Due to the large amount of steel required for the construction and operation platform, the welding and assembly costs are high, and it can only be dismantled after use. Moreover, after the construction platform is dismantled, it is also necessary to cooperate with measures such as high-altitude vehicles, so the cost of curtain wall construction measures far exceeds the cost of measures at the time of bidding. In addition, it can be difficult to maintain the lights and curtain walls after the project is completed.

2. A façade perforated aluminum plate curtain wall project

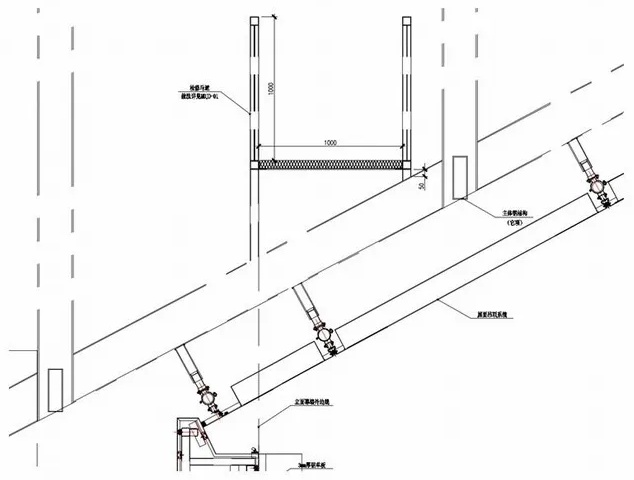

The project is also a renovation of the existing building, the original building is a cylindrical structure, with a height of about 50m, and there are no building function requirements. The renovation project was to add a perforated aluminium curtain wall to the outside of the structure as a decoration and to add flood lighting. The added perforated aluminium curtain wall is a torsional hyperboloid surface, fitted by triangular aluminium panels. A layer of steel platform is erected every 3m or so outside the concrete structure, and then a vertical perforated aluminum curtain wall keel is erected outside the steel platform.

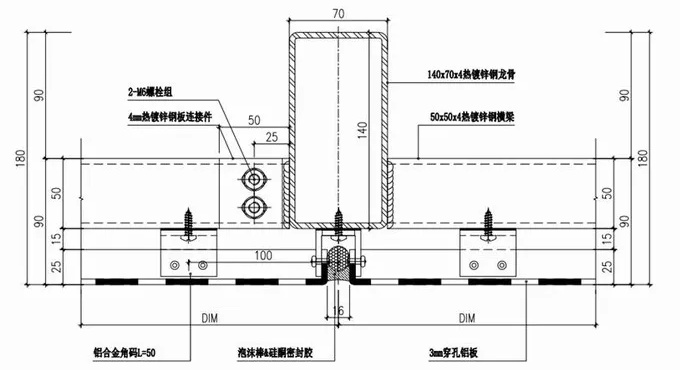

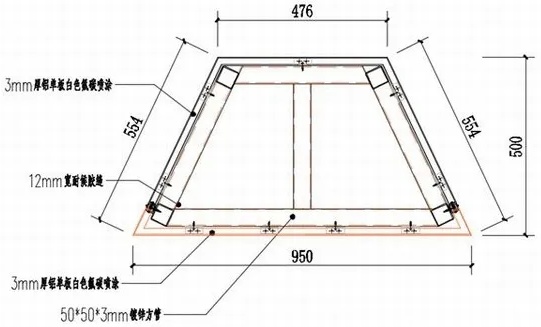

The design of the curtain wall construction drawing adopts the design idea of the conventional perforated aluminum plate curtain wall, which is fixed from the outside. The basic nodes are shown in Figure 4. This design scheme requires construction personnel to work on the outside. Therefore, the construction organization design is mainly to solve how to let the construction personnel can move along the twisted curtain wall, and finally, the construction unit adopts the hanging basket of the cable-stayed guide rail as the main construction tool, and cooperates with the aerial work vehicle as the auxiliary construction tool. This construction method is more costly and the construction progress is slower.

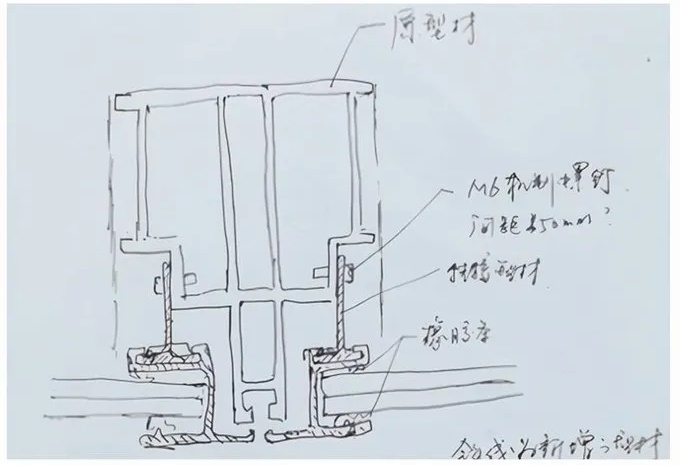

In fact, there is a big difference between this curtain wall and the conventional aluminum panel curtain wall. First of all, the aluminum curtain wall is purely decorative, and there are no performance requirements such as waterproofing and heat preservation. Perforated aluminum plates are used, and there is no need to glue and seal between aluminum plates. Between the twisted aluminum curtain wall and the main structure, there is already a platform erected by the main steel structure as the supporting structure of the aluminum curtain wall, and the scale of this space can fully meet the operation of the construction personnel. Therefore, this steel platform can be considered to be used as the construction platform of the construction personnel, and the mode of installing the aluminum plate curtain wall on the inner side is adopted during the design, which will greatly reduce the difficulty of curtain wall construction. And to provide convenience for subsequent lighting maintenance. Based on the original design structure, we preliminarily conceived a scheme for the installation of the inner side of the aluminum curtain wall of the ceiling. Hand-drawn illustration of Figure 5. This project was not implemented in accordance with the interior decoration method.

The above two projects do not fully consider the particularity of the project in the design stage, and design according to the inertia of conventional curtain wall design, which brings certain difficulties to curtain wall construction and curtain wall maintenance. In fact, the above two projects are not traditional curtain wall structures, in addition to the wind pressure resistance and deformation performance of the curtain wall, there are no other requirements including rainwater infiltration performance, thermal insulation performance, sound insulation performance, etc. If the designer considers an inward-mounted structure, the construction measures can be simplified and the construction efficiency can be improved.

Fourth, the design of the construction of the case

1. The curtain wall of the façade of the revolving restaurant of Yanbian Tower

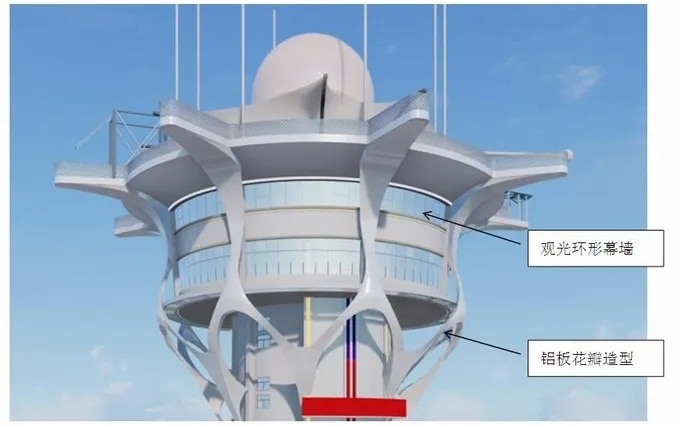

Yanbian Tower is a super high-rise sightseeing tower, which is a renovation project of the curtain wall of an existing building. The building is located in the Yanbian Maoershan Scenic Area, and the site is not conducive to the entry and exit of large machinery. The sightseeing floor of Yanbian Tower has two floors, located at the elevation of 163m, and the hyperboloid petal aluminum plate shape extends from the sightseeing floor to the lower part of the sightseeing floor. The effect of the renovation of the sightseeing layer is shown in Figure 6.

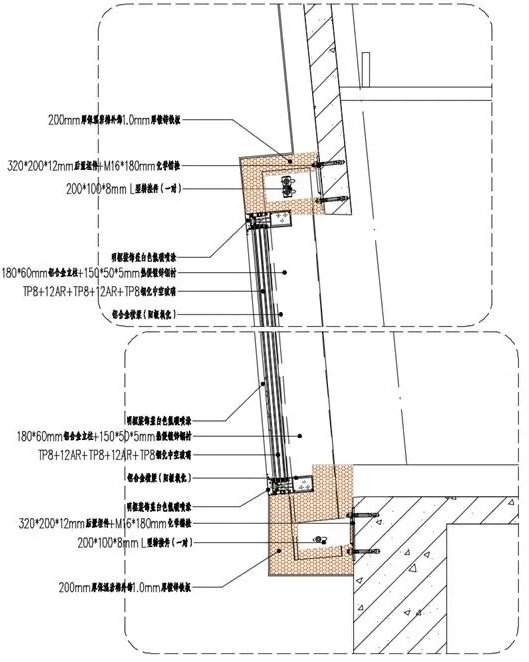

The sightseeing floor of the original building adopts a window, and the renovation is adjusted to a component-type glass curtain wall, and the basic node of the glass curtain wall of the sightseeing layer of the curtain wall design is shown in Figure 7.

According to the curtain wall construction drawings, the construction personnel must go to the outside of the curtain wall to carry out the installation work, which brings great difficulties to the project construction. Through communication with the design unit and Party A, the construction deepening design adjusted this position to the built-in component curtain wall, which was recognized by the design unit and Party A. This kind of internal curtain wall structure, first install the main keel of the curtain wall, and then install the curtain wall glass indoors, simplifies the construction process, and provides convenience for the glass replacement that appears in the subsequent use of the curtain wall. The adjusted curtain wall construction drawings are staked out in the model, fitting the installation sequence and construction to ensure that they can be implemented. The three-dimensional schematic diagram is shown in Figure 8.

2. Yanbian Tower's high-altitude aluminum plate petal shape

A new aluminum plate petal shape is added to the outside of the sightseeing layer of Yanbian Tower, and the aluminum plate shape is fixed on the main structure, and the relationship with the main structure is more complicated. The original design drawing gives the basic method of modeling the cross-section, see Figure 9. Due to the complex shape of the petal aluminum plate, and the large distance between the aluminum plate shape and the main structure, the difficulty of molding and spatial positioning is greater.

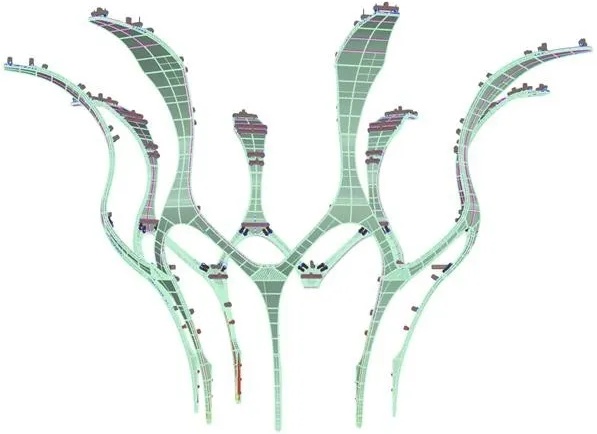

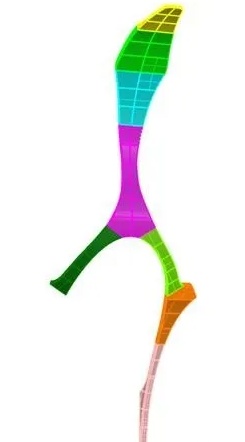

Through communication with the curtain wall design unit, we first re-modeled the entire aluminum plate petals as a whole, optimized the surface of the aluminum plate, and adjusted the distance between the shape and the main structure during the modeling process to avoid excessive cantilever support. The whole shape adopts a large cross-section round steel pipe to find the shape, which is convenient for processing, and the overall model after optimization is shown in Figure 10.

The size of the whole aluminum plate modeling is larger, and if the mode of installing the aluminum plate after the welding steel structure is hoisted first, the construction is difficult. Therefore, the detailed design decomposes the entire aluminum plate petals into 64 independent units, 8 independent units, each of which is expressed in a different color, see Figure 14.

Each aluminium unit, including the circular steel structure of the support and the aluminium trim on the outside, is processed and assembled in the factory, and after being transported to the construction site, each unit body is independently attached. It can better ensure the processing and assembly accuracy of aluminum plate molding. Three-dimensional schematic diagram of the attachment and unit docking nodes of the aluminum plate unit.

3. Haikou duty-free city aluminum plate ceiling

The project is located in Haikou City, which is currently the largest single duty-free city in Asia. The building was designed by VP Architects of France, China Architectural Design and Research Institute Co., Ltd. completed the construction drawing design, and our company is responsible for the design of the façade curtain wall and roof. The metal eaves of the project are large in size, and the basic shape is formed by the cantilever of the main steel structure. The architects designed a large number of floodlights inside the aluminium ceiling. The on-site photos of the aluminum plate cornice are shown in Figure 12.

If the aluminum plate is fixed from the outside, the construction is more difficult, and the maintenance of the flood lamps of the project is difficult. Considering that the space of the steel structure of the upper part of the ceiling is larger, we add a frame to the aluminum plate ceiling plate during the design, and connect and fix the ceiling keel on the inner side, so that although the amount of material is increased, the construction and maintenance are facilitated. The basic nodes are shown in Figure 13.

The floodlight fixtures are pre-installed in the aluminum plate plate, and the construction personnel build a construction road on the inner side of the steel structure of the ceiling, install the aluminum plate plate from the inside of the ceiling, and then connect the power supply of the lamp. The construction horse road is retained after the construction is completed, so as to facilitate the maintenance of the aluminum panels and lights of the ceiling in the future. The horse road provided in the cornice of the main steel structure is shown in Figure 14.

5. Summary

Curtain wall design should be the whole process design of curtain wall materials, processing, assembly, installation and maintenance. Designers should comprehensively consider the problems encountered in curtain wall construction and curtain wall maintenance. The curtain wall design work is not isolated, and it is necessary to combine various departments and specialties, including the production process of materials, processing technology, assembly process of curtain wall components and construction technology of curtain wall installation. Starting from the project as a whole, it provides a reasonable direction for the production, construction and maintenance of curtain wall engineering.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China