1. Project objectives: Through the construction of glass partitions, the decoration effect of clear space zoning, optimized lighting and visual transparency is realized, and the partition structure is safe and durable, which is in line with the overall style positioning of the interior.

2. Applicable scenarios: It is suitable for residential living rooms and study rooms, bedrooms and cloakrooms, bathroom dry and wet partitions, as well as office spaces, commercial exhibition areas and other places that need to be flexibly separated.

3. Glass type selection

Safety glass is the main choice, preferentially tempered glass (strong impact resistance, granular after breaking, high safety), thickness can be 8mm, 10mm, 12mm according to needs.

If you need privacy, you can choose frosted tempered glass (surface frosted treatment, light transmission is not transparent), laminated tempered glass (middle laminated layer, does not fall off after breaking, good sound insulation) or Changhong/water ripple tempered glass (highly decorative, suitable for stylized spaces).

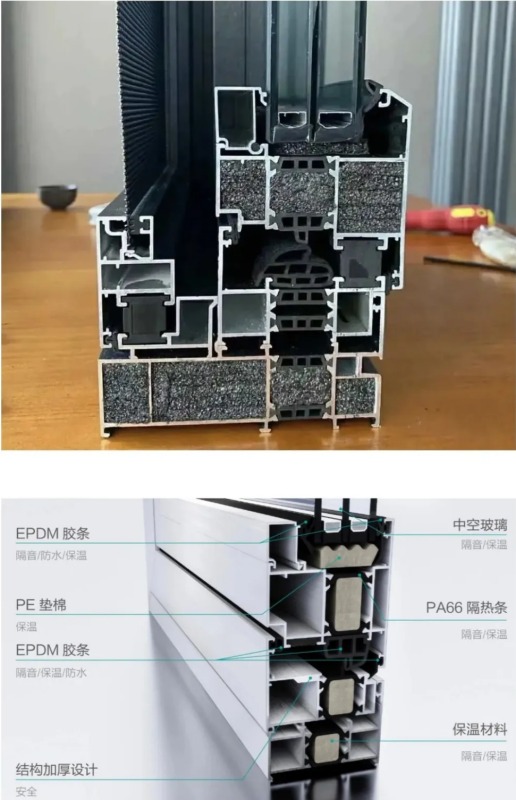

For special needs (such as high sound insulation requirements), double-layer insulating tempered glass (middle air layer or inert gas, good sound insulation and heat insulation effect) can be selected.

2. Pre-construction preparation

(1) Design and planning

1. Dimensional measurement: Accurately measure the length, width and height of the partition installation position, including ground flatness, wall verticality, and top horizontality, record data and mark the error range (ground error >5mm needs to be leveled in advance).

2. Drawing design: Draw construction drawings according to the measurement data, clarify the size, shape (such as straight, L-shaped, arc), fixing method, closing details, and connection with the surrounding wall/ground/top surface, and mark the glass model, thickness and hardware accessory specifications.

3. Style matching: Determine the glass type, frame material (such as aluminum alloy, stainless steel, wood) and color based on the overall interior decoration style to ensure that the partition is coordinated with the wall and furniture tone.

(2) Preparation

of materials and tools 1. Material procurement

Glass: Customized according to the specifications of the drawings, the 3C certification report of tempered glass is required, and the size, thickness, and surface treatment of the glass are consistent with the drawings.

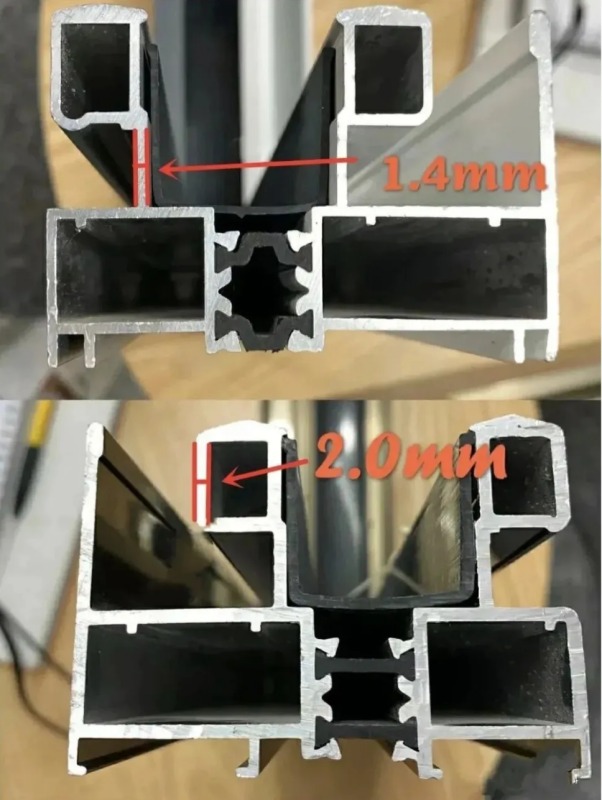

Frame/frame material: Choose aluminum alloy profiles (lightweight, corrosion-resistant, suitable for modern style), stainless steel profiles (strong, strong, suitable for industrial/light luxury style) or wooden frames (warm and natural, suitable for Nordic/Japanese style) according to the design, ensuring that the profile wall thickness meets the standard (aluminum alloy frame wall thickness ≥ 1.2mm).

Hardware accessories: including glass fixing clips, hinges (if you need to open the fan), floor springs (frameless glass doors), sealing strips (silicone material, waterproof and sound insulation), expansion bolts, screws, glass glue (neutral silicone glass glue is optional, waterproof and mildew-proof, color matching frame or wall).

Auxiliary materials: floor/wall leveling materials (cement, gypsum mortar), base layer treatment, anti-rust paint (for metal fittings connections).

2. Tool preparation: laser level, tape measure (more than 3 meters), electric drill, impact drill, glass suction cup (load-bearing≥ glass weight 1.5 times), glass knife (spare, for on-site fine-tuning), angle grinder (cutting border profile), screwdriver, glue gun, level, ruler, cleaning tool (glass cleaner, rags, scrapers).

(3) On-site preparation

1. Site cleaning: remove debris and dust in the partition installation area, ensure that the construction site is smooth and smooth, and protect the surrounding renovated ground (laying mulch film or thick cardboard), walls (pasting protective film), doors, windows and furniture.

2. Base treatment

Wall: If it is a solid wall, check whether the wall is hollow or cracked, and the empty area needs to be shoveled and re-plastered; If it is a lightweight partition wall (such as a gypsum board wall), the position of the keel should be confirmed, and a lining plate (woodworking board or steel plate) should be added at the fixed point to enhance the load-bearing.

Ground: clean up the oil and impurities on the ground, level the uneven ground with cement mortar, and polish it after drying to ensure that the surface is flat and smooth.

Top surface: Check whether the top surface is firm, if the top surface needs to be fixed, confirm the load-bearing capacity of the top base layer (concrete, ceiling keel), and install load-bearing brackets if necessary.

3. Water and electricity pipeline inspection: Confirm the installation location of the partition and the direction of the surrounding water and electricity pipelines (water pipes, wires, network cables) with the owner or decoration electrician, mark the location of the pipelines and avoid them to avoid damaging the pipelines during construction.

3. Construction process and details

(1) Framework/ Border installation (suitable for framed glass partitions)

1. Pay-off positioning: According to the construction drawings, use a laser level to pop up the center line, frame position line and fixed point marks of the partition on the ground, wall and top to ensure that the line is straight and the position is accurate.

2. Border cutting and assembly: cut the frame profile according to the pay-off size (aluminum alloy/stainless steel profile needs to be cut with an angle grinder, the cut is polished smooth), drill holes at the connection of the profile, assemble it into a frame by screws or connectors, and check the square of the frame (diagonal error ≤3mm).

3. Frame fixation

Ground fixation: align the bottom edge of the frame with the ground positioning line, Drill holes with an electric drill at the fixing point, implant expansion bolts, and tighten the bolted fixed frame (set a fixing point every 60 cm, and the corners need to be encrypted).

Wall fixing: The side of the frame is fitted to the wall, and fixed with expansion bolts after drilling, if the wall is gypsum board, it needs to be penetrated to the keel or liner to fix it to ensure firmness.

Top surface fixing: the top surface of the frame is aligned with the positioning line of the top surface, the drilling and fixing method is the same as the ground, and the verticality (deviation ≤ 2mm/m) and horizontality (deviation ≤1mm/m) of the frame are checked after fixation.

4. Anti-rust treatment: The metal frame connection and the exposed part of the screw are coated with anti-rust paint to prevent rust in the later stage.

(2) Glass installation

1. Glass handling and cutting: Glass handling requires the cooperation of more than 2 people, using glass suction cups to assist to avoid one-handed handling or collision with corners; If the glass size needs to be fine-tuned, use a glass knife to slightly cut the edges, and then sand the edges with sandpaper to remove burrs.

2. Glass positioning and fixation

Framed partition: Install a glass spacer (silicone material, thickness 5-10mm, set every 50cm) on the inside of the frame, slowly put the glass into the frame, ensure that the gap between the glass and the frame is uniform (single-side gap 2-3mm), and the bottom of the glass should completely fall on the spacer to avoid direct contact with the frame.

Frameless partition: Install the glass clip or fixing piece according to the fixing method, after the glass clip is firmly fixed with the wall/ground/top surface, the glass is embedded in the clip, and the screw of the clip is tightened after adjusting the position (the screw needs to be covered with rubber pads to avoid scratching the glass).

Curved glass partitions: Slowly embedded in the frame according to the pre-customized curved frame or curved glass size to ensure a tight fit between the glass and the frame, and if necessary, fix it with temporary supports.

3. Glass splicing treatment: When multiple pieces of glass are spliced, the width of the splicing seam should be controlled at 2-5mm, and the gap should be straight.

(3) Frameless glass partition/glass door installation (suitable for frameless design)

1. Floor spring installation(Glass door): Mark the position of the ground spring according to the drawing, excavate the installation groove at the corresponding position on the ground (the depth and size are determined according to the specifications of the ground spring), put in the ground spring and level it, fix it with cement mortar, and connect the ground spring shaft after the mortar solidifies (at least 24 hours).

2. Glass door fixation: Install the ground spring connector at the bottom of the glass door, install the door clamp on the top, adjust the position of the door clamp and the ground spring shaft, ensure that the glass door opens and closes smoothly, without stuttering or shaking, and the gap between the door and the door frame is uniform (1-2mm on one side).

3. Fixed glass installation: the frameless fixed glass is connected to the wall, ground and top surface through glass glue or special glass fixtures, the installation distance of the fixtures is ≤ 80cm, and the bottom of the glass needs to be pad with silicone spacers to prevent moisture.

(4) Sealing and closing treatment

1. Glass glue filling: At the gap between the glass and the frame, the glass and the wall/ground/top surface, use a glue gun to evenly inject neutral silicone glass glue (the glue nozzle is cut into a 45° angle to ensure that the glue line is full and smooth), the width of the glue line is controlled at 3-5mm, and after injection, use a scraper to lightly scrape the glue surface to remove excess glass glue and ensure a flat surface.

2. Border closing: If there is a gap at the junction of the framed partition with the wall and the ground, use the same color glass glue or decorative lines (such as stainless steel edging strips, wooden lines) to close the mouth, and the lines should be firmly fixed, flat and straight.

3. Anti-collision treatment: Anti-collision strips (silicone, color matching glass or frame) can be installed at the sunny corners of the glass partition, and the height is recommended to be 1.2-1.5m to prevent collision injuries; the installation position of the glass door handle should avoid blind spots to ensure safe use.

(5) Construction details

of special scenes 1. Bathroom glass partition

Waterproof treatment: The contact between the ground and the bottom of the glass should be painted with waterproof paint (extending to the inside of the glass by more than 10cm), and the gap between the bottom of the glass and the ground should be filled with anti-mold glass glue to ensure waterproof sealing.

Installation of water barriers: Install stone or aluminum alloy water strips (height ≥ 2cm) on the outside of the bottom of the glass partition, and fix the water barriers with anti-mold glass glue to prevent water from overflowing.

Ventilation considerations: If it is a closed partition, it is necessary to reserve ventilation gaps or install blinds to avoid dampness and stuffiness in the bathroom.

2. Double-layer insulating glass partition: ensure that the spacing between the two layers of glass is evenly spaced during installation, sealed with sealing rubber strips around it, and the expansion space should be reserved at the connection between the glass and the frame to avoid glass deformation caused by temperature changes.

3. Curved glass partition: The curvature of the frame should be exactly matched with the curvature of the glass, and the gap should be slowly embedded during installation, and the gap should be filled with flexible glass glue to ensure that the glass is evenly stressed and there is no local extrusion.

4. Quality acceptance standards

1. Appearance quality: There are no scratches, bubbles, impurities or cracks on the glass surface, the glass glue line is full and smooth, no bubbles, no peeling, and the surface of the frame/frame is flat, no deformation, no scratches, and the color is the same.

2. Structural safety: the glass is firmly fixed, there is no loosening or shaking, the verticality deviation of the frame is ≤2mm/m, the horizontality deviation is ≤1mm/m, the diagonal error is ≤3mm, and the gap between the glass and the frame is uniform.

3. Functional performance: the glass door opens and closes smoothly, no abnormal noise, accurate positioning (no rebound or shaking after closing), soundproof glass partition needs to be tested for sound insulation effect (can be detected by noise meter, the insulation volume meets the design requirements), and the sanitary partition needs to be closed water test (no leakage for 24 hours).

4. Detail treatment: the closing line is straight, the connection with the surrounding area is natural, there are no obvious gaps, the anti-collision strip is firmly installed, and the hardware accessories are not loose or rusty.

5. Construction safety and precautions

1. Construction safety

Operators need to wear gloves and goggles, and handle the glass gently when handling it to avoid glass collision and breakage, and the broken glass needs to be cleaned in time and stored separately to prevent scratches.

Electrical equipment (electric drill, angle grinder) should be checked to be intact, grounded reliably, and kept away from water sources when using to avoid electric shock.

For high-altitude work (such as top frame installation), scaffolding or ladders should be used to ensure stability, and it is strictly forbidden to stand on window sills or unstable objects.

2. Material protection: glass storage should be placed vertically on a flat ground, with a wooden cushion at the bottom to avoid direct sunlight and rain; The frame profile avoids collision and deformation, and is stored in a dry and ventilated place to prevent rust or moisture.

3. Environmental requirements: The environmental temperature of glass glue construction should be between 5-35°C, the humidity ≤ 85%, and avoid touching the glass and glass glue within 24 hours after construction to prevent the deformation of the glue wire.

4. Protection of finished products: After the construction is completed, paste a protective film on the glass surface (at least until the completion of the overall decoration) to avoid scratching the glass during the construction of other processes; The glass door can be temporarily fixed to prevent shaking caused by accidental touch.

6. Later maintenance and maintenance

1. Cleaning and maintenance: Wipe the glass surface with a soft rag dipped in water or neutral glass cleaner every day, avoid using wire balls, strong acids and alkali cleaners to prevent scratching or corroding the glass; Regularly clean the dust in the gaps of glass glue to maintain the sealing effect.

2. Hardware maintenance: Regularly check hardware accessories such as glass clips, hinges, and floor springs, and tighten them in time if they are loose, and apply a small amount of lubricating oil to the moving parts to ensure smooth opening.

3. Problem treatment: If there are slight scratches on the surface of the glass, you can try to repair it with glass polish; When the glass glue cracks or falls off, the old glue needs to be removed and re-glued; If you find cracks in the glass or loose frame, you need to contact professionals in time to repair and replace it to avoid potential safety hazards.

7. Safety norms and emergency measures

1. Safety norms: Construction personnel must wear safety helmets, non-slip gloves, and fasten safety belts when working at height; wear goggles when cutting and polishing glass to avoid splashing and injuring people; Smoking is prohibited at the construction site and fire extinguishers are provided.

2. Emergency measures: If glass breaks, stop construction immediately, evacuate personnel, clean up debris with tools (avoid unarmed contact), and enclose the site with warning belts; If the person is scratched by glass, immediately use clean gauze to stop the bleeding, and send him to the hospital for treatment in severe cases; If the water and electricity pipelines are damaged, close the main gate immediately and contact professionals to deal with it.

Through the above comprehensive construction plan and detailed control, it can ensure that the construction quality of glass partitions meets the standards and achieve beautiful, practical and safe decoration effects.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China