Glass curtain wall engineering construction technical scheme

Glass curtain wall engineering construction technical scheme

Glass curtain wall refers to the building perimeter structure or decorative structure that can have a positioning and displacement ability relative to the main structure by the supporting structure system and does not share the effect of the main structure. The walls are available in single and double glazing. Glass curtain wall is a beautiful and novel architectural wall decoration method, which is a distinctive feature of the modernist high-rise building era.

1. Advantages of glass curtain wall

1. Strong aesthetics: The glass curtain wall has a transparent and simple visual effect, which can integrate with the surrounding environment, show the fashion sense and sense of technology of modern architecture, and enhance the overall aesthetics and symbolism of the building.

2. Good lighting effect: A large area of glass can allow more natural light to enter the room, reducing the dependence on artificial lighting during the day, creating a bright and comfortable indoor environment, and helping to save energy.

3. Wide field of view: Indoor personnel can clearly see the outdoor scenery through the glass curtain wall, enhance the sense of openness of the space, and improve the comfort of living or working.

4. Light weight: Compared with traditional masonry, concrete and other wall materials, the dead weight of glass curtain wall is lighter, which can reduce the load of the building structure and reduce the cost of infrastructure construction.

5. Convenient construction: glass curtain walls mostly use prefabricated components, which have high on-site installation efficiency, which can shorten the construction period and improve the progress of building construction.

6. Easy maintenance: Some glass curtain walls are designed with openable fans and easy to clean structures, while the glass surface is smooth, not easy to accumulate dust, and daily maintenance is relatively simple.

2. Disadvantages of glass curtain wall

1. High energy consumption: The thermal insulation performance of glass is poor, which can easily lead to high indoor temperature in summer, and will lose indoor heat in winter, increasing the frequency of air conditioning and heating, thereby consuming more energy.

2. Serious light pollution: Glass curtain walls will produce reflected light under sunlight, which may cause light pollution to the surrounding environment and affect the life and safety of residents.

3. Safety hazards: If the construction quality of the glass curtain wall is not up to par or the use time is too long, the glass may be broken and fallen off, posing a safety threat to pedestrians and surrounding facilities.

4. Poor sound insulation effect: The sound insulation performance of glass is relatively weak, and outdoor noise is easy to transmit into the room through the glass curtain wall, affecting the quiet indoor environment.

5. Difficult to clean: For the glass curtain wall of high-rise buildings, the cleaning of the outer glass requires professional equipment and personnel, which is not only costly, but also has certain safety risks.

6. Easy to produce condensation: In the case of a large temperature difference, the inside of the glass curtain wall is prone to condensation, affecting the comfort of the indoor environment, and may also damage the structure and decoration inside the wall.

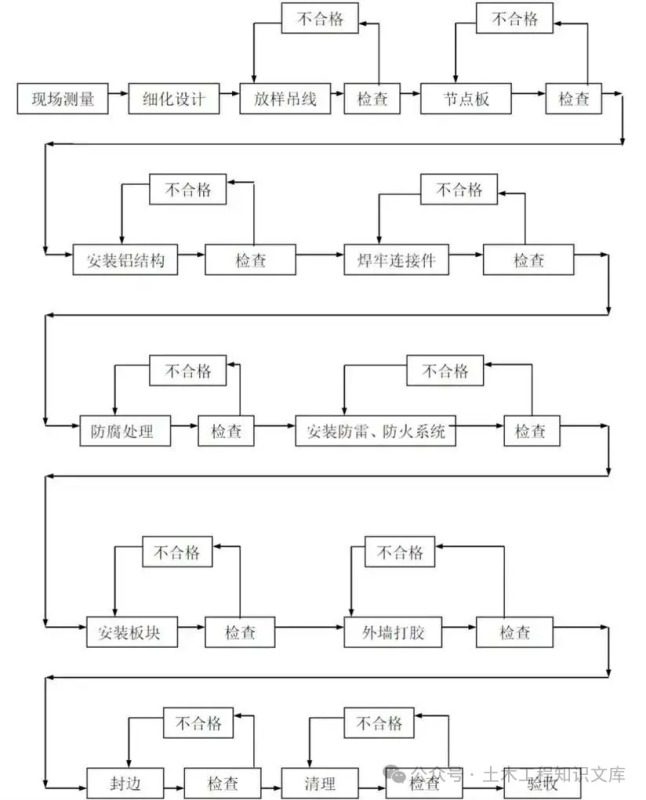

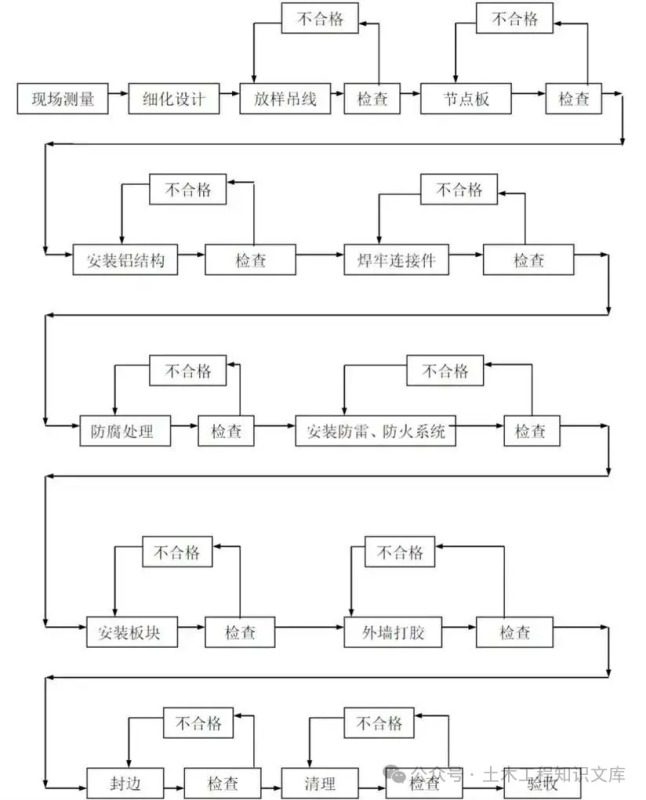

3. Curtain wall installation and construction process

4. Curtain wall construction plan

1. Construction preparation

(1) Treat the skeleton itself

Pay attention to the protection of the skeleton oxide film, and anti-corrosion treatment of the oxide film at the part in direct contact with the concrete. The skeleton is connected by connectors, which are threaded into the ends of the upper and lower members respectively, and then tightened with bolts.

(2) Key points of construction and installation

1) Mullions installation requires accuracy and compliance with quality standards. The joints are connected by sleeves, leaving a certain gap in the joints. The connection between the connector and the embedded part adopts a rigid joint structure.

2) Before installing the column, carefully check whether the specifications, size, quantity and number of the columns are consistent with the construction drawings.

3) First connect the mullions with the connectors, then connect the connectors with the main embedded parts, and adjust and fix the mullions, the installation elevation deviation is controlled within 3mm, the axis front and rear deviation is within 2mm, and the left and right deviation is 3mmWithin. At the same time, pay attention to the error should not accumulate, and the window opening is a positive tolerance.

4) The installation elevation deviation of adjacent mullions should not be greater than 3mm, the maximum elevation deviation of mullions on the same floor should not be greater than 3mm, and the distance deviation of adjacent mullions should not be greater than 2mm. The allowable deviation and inspection method of mullion installation shall comply with the provisions of the following table.

project

|

Deviations allowed

|

Inspection method

|

mullframe verticality

|

10

|

Use theodolite or laser

|

mullion straightness

|

3

|

Use a 3m ruler

|

Surface flatness of three adjacent columns

|

<2

|

Use a laser device

|

Flatness of the outer surface of the mullion

|

≤5

|

Use a laser device

|

5) An anti-corrosion isolation gasket must be added between the mullion and the contact surface of the connector (bearing).

6) The mullion should be self-inspected after preliminary positioning according to the deviation requirements, and the unqualified ones should be adjusted and corrected. The number of sampling inspections is more than 5% of the total number of mullions, and not less than 5 pieces. After passing the sampling inspection, the connectors (bearings) are officially welded firmly.

7) The mullions are installed in place, and fixed in time after adjustment. The temporary bolts installed on the glass curtain wall should be removed in time after the components are installed, in place, adjusted and fixed.

8) The welding site must take fire and explosion-proof safety measures before operation. The grounding neutral wire and welding working line of the welding machine must comply with relevant safety regulations.

9) After the mullion is installed firmly, the standard block used to position the expansion joint between the upper and lower mallions must be removed, and sealant must be applied at the expansion joint.

2. Installation of curtain wall components

(1) Select sealing materials

1) First, line the aluminum alloy frame with elastomeric materials such as neoprene to prevent damage caused by the expansion and contraction of the glass caused by temperature changes.

2) The width control of the rubber pad should not exceed the width of the glass, and the length should be determined according to the quality of the glass.

3) For the sealing material on both sides of the groove, first use a long rubber strip as the caulking material, and then inject a waterproof sealant on the caulking material. The sealant is made of silicone sealant, which is required to be uniform and full, and the injection depth is about 5mm.

(2) Measurement and payoff

1) Clean up the residual cement ash sand on the embedded surface.

2) Use the internal control method to establish the vertical reference line and façade control network of the curtain wall, and use the laser theodolite and plumb meter to measure the vertical reference line and establish the façade control network.

3) Determine the horizontal base accuracy line: Based on the measurement of the datum elevation reference point, use a long tape measure to measure the elevation line of each point, and then use a level to level at the same point, make a mark, and use this mark to control the horizontal installation position of the column.

(3) Curtain wall skeleton installation

Column mounting

|

Check the column model, specification→ alignment is in place→ insert the core sleeve at the lower end of the fixed beam→ fix the empty bolt at the upper end of the beam→ three-dimensional adjustment→ tighten the nut, spot weld decoding and the connection of embedded parts.

|

beam mounting

|

Construction preparation→ check the quality of various materials→ in-place installation → inspection.

|

(4) Installation of connectors

Familiar with drawings and technical disclosure→ familiar with the construction site→ find the alignment of embedded parts on the column line→ horizontal line control→ level height and depth position temporary fixation→ inspection→ and final fixation → anti-corrosion → records

1) Familiarize yourself with drawings and technical disclosure: Construction personnel need to carefully study the design drawings and clarify key information such as the model, specification, installation location and connection method of the connectors. At the same time, participate in the technical disclosure meeting to understand the construction technical requirements, quality standards, safety precautions and important and difficult points in the construction to ensure a comprehensive and accurate grasp of the construction content.

2) Familiarize yourself with the construction site: After entering the construction site, you should fully understand the structure of the site, axis position, elevation control points, etc., and check whether the construction site has the installation conditions, such as whether there are obstacles and whether the scaffolding erection meets the requirements. At the same time, check whether the actual situation on site is consistent with the drawing design, and find and feedback the existing problems in time.

3) Align the embedded parts with the column line: accurately find the embedded parts pre-buried in the building structure according to the position marked on the drawings. The connectors are corresponded to the embedded parts, and the position of the connectors is consistent with the line position of the column, so as to ensure the accuracy of the column installation and lay the foundation for the stability of the subsequent curtain wall structure.

4) Horizontal line control horizontal height and depth position: use level and other measuring tools to lead the horizontal line, which is used as a reference to control the horizontal height of the connector to ensure that each connector is on the same horizontal plane. At the same time, according to the design requirements, the depth position of the connector is determined by measurement to ensure that it meets the overall installation size of the curtain wall.

5) Temporary fixation: After the position, height and depth of the connector are adjusted in place, temporary fixation measures are adopted, such as bolts or spot welding to preliminarily fix the connector on the embedded part to prevent it from displacement in subsequent operations and provide stable conditions for subsequent inspection and adjustment.

6) Inspection: Conduct a comprehensive inspection of the temporarily fixed connectors, including whether their position, elevation, verticality, flatness, etc. meet the design and specification requirements. Use measuring tools such as levels and theodolites for accurate measurement, and if deviations are found, adjust them in time to ensure the accuracy of connector installation.

7) Final fixing: After checking and confirming that the installation of the connectors meets the requirements, the final fixation is carried out according to the connection method specified in the design. If welding is used, the welding quality must be ensured, and the height and length of the weld should meet the standards; If bolted connections are used, the bolts need to be tightened to ensure a strong and reliable connection.

8) Anti-corrosion: anti-corrosion treatment of connectors and welding parts. First, clean the surface of rust, welding slag and other debris, and then apply anti-rust paint or take other anti-corrosion measures to prevent the connectors from affecting their strength and service life due to corrosion during use.

9) Record: Record in detail the relevant information of the installation of connectors, including installation location, quantity, model, fixing method, inspection results, anti-corrosion treatment, etc., to form a complete construction record. These records are not only an important basis for project quality acceptance, but also facilitate subsequent maintenance and management.

(5) Curtain wall lightning protection

1) After the installation of the connectors is completed, the curtain wall column installation is also followed up with the construction of lightning protection.

2) It is necessary to ensure that the vertical lightning protection belt of the curtain wall is composed of vertical aggregates that are electrically connected above and below, so that the curtain wall has a unified lightning protection system.

3) Since the connection between the upper and lower vertical aggregates is connected by plug-ins and injected with sealant, our company designs a connecting wire and fixes it on the upper and lower columns with screws.

(6) Glass curtain wall installation

1) The glass frame should be cleaned as necessary before installation to ensure that the caulking weathering adhesive can be reliably bonded. The coating surface of the glass should be protected by a protective film before installation, and then removed before handover.

2) The variety, specification and color of the glass should be consistent with the design requirements, the color of the whole curtain wall glass should be uniform, and the coating surface of the glass should be oriented towards the indoor direction.

3) The glass frame should be protected during installation to avoid collisions, damage, or falls.

4) The hooks, briquettes or other connectors used to fix the glass frame should be strictly implemented in accordance with the design requirements or relevant specifications, and it is strictly forbidden to install less or no fastening screws.

5) The grid glass seams should be vertical and horizontal, with uniform seam width, and meet the design and deviation requirements.

3. Window sash installation and construction

(1) Necessary cleaning should be carried out before the installation of the sash, and pay attention to the gap between the sash and the window frame up, down, left and right, front and back, inside and outside to ensure its tightness.

(2) The specifications, varieties and quality of sash connectors must meet the design requirements, and stainless steel or light metal products should be used, and the diameter of the bottom hole of the self-tapping screw should be strictly controlled.

4. Sealing treatment

(1) After the glass or glass components are installed, they must be caulked with weather-resistant sealant in time to seal them to ensure the air tightness and water tightness of the glass curtain wall.

(2) The construction of weather-resistant silicone sealant for glass curtain wall sealing treatment should meet the following requirements:

(3) The construction of weather-resistant silicone sealant should ensure that there are no water, oil stains, rust, cement mortar, dust and other debris in the seam.

(4) The construction thickness of weather-resistant silicone sealant should be greater than 3.5mm, and the construction width should not be less than 2 times the construction thickness. After glue injection, the surface of the glue seam should be scraped flat and excess sealant should be removed.

(5) The weather-resistant silicone sealant should form a two-sided bond in the seam, not three-sided, and the bottom of the deep sealing notch should be filled with polyethylene foam material.

(6) The sticker base tape should be removed immediately after the glue is filled and scraped flat.

(7) When sealing with rubber strips, the rubber strips should be selected strictly according to the design specifications, the inlay should be flat, the length of the rubber strip should be 1.5%-2% longer than the notch in the frame, and its fracture should be left in the four corners. After the inclined surface is disconnected, it should be assembled into a predetermined design angle, and it should be firmly bonded with adhesive and embedded in the groove.

(8) The joints or other gaps on the inner and outer surfaces of the curtain wall should be continuously sealed with sealants similar in color to the surrounding objects, and the joints should be flat, smooth, and tight without leakage.

5. Protection and cleaning

(1) Appropriate measures should be taken to protect the curtain wall during construction to prevent collision, pollution, deformation, discoloration and blockage of drainage pipes.

(2) During construction, the adhesives that affect the surface decoration of the curtain wall and curtain wall components should be removed in time to restore its original state and appearance.

(3) After the installation of the glass curtain wall project is completed, a cleaning plan should be formulated to prevent pollution and abnormalities on the surface of the curtain wall, and the cleaning tools, hanging trays, cleaning methods, time, procedures, etc. should be approved by full-time personnel.

(4) After the installation of the curtain wall is completed, the surface of the curtain wall and exposed components should be cleaned with neutral cleaning agent from top to bottom.

5. Quality control measures for glass curtain wall installation

1. Material quality control

Strictly control the entry of raw materials, and all materials used for glass curtain wall installation, such as glass, profiles, connectors, sealants, etc., must be checked for quality certification documents such as factory certificates and performance test reports to ensure that the materials meet relevant national standards and design requirements.

Sampling and re-inspection of incoming materials, such as the thickness of glass, light transmittance, impact resistance, mechanical properties of profiles, wall thickness, adhesion performance of sealants, aging resistance, etc., only materials that pass the re-inspection can be put into use, and unqualified materials are not used in the project.

The storage of materials should comply with regulations, the glass should avoid exposure to the sun and rain, and should be placed at an angle and anti-slip measures should be taken when storing; The profile should be placed in a dry and ventilated place to prevent rust; The sealant should be stored under the specified temperature conditions to avoid failure.

2. Quality control in the construction preparation stage

Before construction, technical personnel are organized to conduct in-depth review of the design drawings, familiarize themselves with the technical requirements, node structure and construction difficulties in the drawings, and ensure that the construction personnel accurately understand the design intention. If there are doubts or unreasonable points in the drawings, communicate with the design unit in time to solve them.

Prepare detailed construction organization design and special construction plans, clarify the construction process, quality control points of key processes, safety measures and emergency plans, etc., and strictly implement them after approval.

Conduct comprehensive technical disclosure and training for construction personnel to familiarize them with construction technology, quality standards and safety operating procedures. Special operators such as welders and cranes must hold certificates to ensure the standardization of construction operations.

3. Measurement and pay-off quality control

Before measuring and paying off, the reference point, axis and elevation of the construction site are reviewed to ensure the accuracy of the measurement basis. Use calibrated and qualified measuring instruments, such as total stations, levels, theolites, etc., to measure and release according to the design requirements.

The measurement and pay-off line should follow the principle of "from the whole to the part, control first and then the details", first establish a unified measurement and control network, and then release the axis, side, elevation line, etc. of the curtain wall on this basis. During the pay-off process, it should be reviewed multiple times to reduce the measurement error.

For the glass curtain wall of high-rise buildings, considering factors such as settlement and temperature difference deformation of the building structure, an appropriate amount of deformation should be reserved when measuring the pay-off line to ensure that the curtain wall will not be damaged due to structural deformation during use.

4. Frame installation quality control

Columns and beams are the main stressed components of glass curtain walls, and their installation position, verticality and flatness must be strictly controlled. When installing the column, it should be temporarily fixed first, and then its verticality should be checked with a theodolite, and the deviation should be controlled within the allowable range of the specification, and the final fixation should be carried out after the adjustment is qualified.

The beam should be installed perpendicular to the column, and its elevation deviation and joint height difference should meet the requirements. The connection nodes between the beam and the column should be firm and reliable, in line with the design regulations, and prevent loosening.

After the frame is installed, it is comprehensively inspected, including the spacing, straightness, verticality, flatness, etc. of the columns and beams, to ensure the overall stability and installation accuracy of the frame.

5. Quality control of glass installation

Before glass installation, clean the stains and debris on the glass surface and the contact part of the frame, check whether the size and specifications of the glass are consistent with the design, and whether the glass edge is damaged and other defects.

When the glass is installed, the positioning and load-bearing spacers are correctly placed according to the design requirements to ensure that the glass is subjected to uniform force. Avoid hard collisions between the glass and the frame during installation and prevent glass damage.

The sealing treatment of glass should be strictly controlled, and the sealant should be applied evenly to ensure that the glue seam is full, continuous, and free of bubbles, and is firmly bonded with the glass and frame. The width and thickness of the glue seam should meet the design requirements to ensure sealing performance and prevent rainwater leakage.

6. Quality control of connector installation

The connection between the connector and the embedded part of the building structure must be firm, if welded connection is adopted, the height, length and fullness of the weld should meet the design and specification requirements, and the anti-corrosion treatment should be carried out in time after the welding is completed; If bolted connections are adopted, the specifications and quantities of bolts should meet the requirements, and the tightening torque should reach the specified value, and there should be anti-loosening measures.

The installation position, elevation, depth and other parameters of the connectors should be accurate, and the installation process should be measured and checked multiple times to ensure that the design requirements are met and avoid problems in the subsequent frame and glass installation due to the installation deviation of the connectors.

7. Sealing and waterproof quality control

The sealing rubber strip of the curtain wall should be selected with products with good aging-resistant and good elasticity, and the installation should ensure that the rubber strip is continuous and free of breakage, and that it fits closely with the glass and frame to play an effective sealing role.

For the opening fan of the curtain wall, it is necessary to ensure that it is closed tightly, the compression of the sealing strip is uniform, the hardware accessories are firmly installed, the opening is flexible, and there is no leakage after closing.

During the construction process, it is necessary to do a good job in rainwater leakage test, and after the installation of the curtain wall is completed, the waterproof performance of the curtain wall should be checked by artificial water spray or natural rainfall, and the leakage points should be repaired in time.

8. Inspection and acceptance during the construction process

The construction unit should establish a complete quality self-inspection system, arrange full-time quality inspectors to inspect each process, check whether the construction meets the design and specification requirements, issue rectification notices in a timely manner for the quality problems found, and track the rectification until it is qualified.

After the completion of each process, the process acceptance must be carried out, and the next process can be constructed only after the previous process is accepted. Detailed records should be made during acceptance, including inspection items, inspection results, rectification status, etc.

The acceptance of concealed projects should be strictly controlled, such as the connection between the connection and the embedded parts, the fixed nodes of the frame and other hidden parts, which must be inspected and accepted before concealment, and can only be concealed after passing the acceptance and signing the record.

9. Quality control of finished product protection

After the installation of the glass curtain wall is completed, timely measures should be taken to protect the finished product to avoid damage to the curtain wall during the subsequent construction process. For example, a protective film is applied to the surface of the glass to prevent scratches; The opening fan is temporarily fixed to prevent collision deformation.

It is strictly forbidden to carry out welding, cutting and other operations near the curtain wall, and if it must be carried out, effective fire prevention and anti-pollution measures should be taken to avoid sparks burning the glass or welding slag from contaminating the surface of the curtain wall.

When cleaning the surface of the curtain wall, use a soft rag and neutral detergent, and avoid using hard tools or aggressive cleaners to prevent damage to the coating on the surface of the glass and profiles.

10. Data management quality control

Timely collect and sort out various quality records during the installation of glass curtain walls, including material quality certification documents, re-inspection reports, construction records, measurement and pay-off records, hidden engineering acceptance records, process acceptance records, test reports, etc.

The filling of information should be true, accurate, complete and standardized, and the signing procedures should be complete, which can fully reflect the construction quality of the project and provide a reliable basis for the completion and acceptance of the project.

6. Safety management measures for glass curtain wall installation and construction

1. Safety preparation before construction

Qualification review and personnel training: The construction unit must have the corresponding construction qualifications, and it is strictly forbidden to construct without qualifications or beyond the scope of qualifications. Strict safety training is carried out for all personnel involved in the construction, including safety operation procedures for glass curtain wall installation, precautions for high-altitude work, emergency treatment methods, etc., and can only be taken up after passing the assessment. Special operators such as cranes, welders, frame workers, etc. must hold valid certificates and the certificates are within the validity period.

Safety technical disclosure: Before construction, the technical person in charge needs to make detailed safety technical disclosure to the construction team, and clarify the safety risk points and preventive measures of each process based on the actual situation of the project. The disclosure needs to form a written record, signed by both parties, to ensure that each construction personnel clearly understand the safety requirements of their positions.

Preparation of construction plan and emergency plan: Prepare a special construction safety plan, covering the construction process, safety protection measures, construction equipment safety management, etc., and be approved by the supervision unit and the construction unit. At the same time, formulate a complete emergency plan, clarify emergency organizations, emergency response procedures, rescue measures and material reserves for possible accidents such as falls from high altitudes, object strikes, glass breakage, and fires, and regularly organize emergency drills to improve emergency response capabilities.

Equipment and material safety inspection: Conduct a comprehensive inspection of the machinery and equipment required for construction (such as cranes, gondolas, welding machines, etc.) to ensure that the equipment has good performance, complete and effective safety devices, and regular maintenance records. Check the lifting and transportation plans of glass, profiles, connectors and other materials to avoid safety accidents caused by unstable material stacking or falling during transportation.

2. Safety management of high-altitude work

Scaffolding and work platform safety: Scaffolding must meet national standards and be constructed by professionals and accepted before use. The work platform (such as gondola and aerial work vehicle) needs to be tested and qualified, and check whether its suspension device, braking system, safety lock, etc. are normal before use.

Fall prevention measures: Height workers must wear qualified safety belts, helmets, and non-slip shoes. Protective railings are set up around the building, with a height of not less than 1.2 meters, foot plates are set at the bottom of the railings, and safety warning signs are hung on the protective railings. Sealing or covering protective facilities at the reserved openings, elevator shafts and other parts to prevent personnel from falling.

Working environment safety: In case of severe weather such as strong winds of level 6 or above, heavy rain, thunder and lightning, it is strictly forbidden to work at height. When working in high temperature weather, reasonably arrange the construction time, avoid high temperature periods, and equip heatstroke prevention and cooling supplies; When working in severe cold weather, do a good job of anti-freezing and warmth measures to prevent frostbite of personnel.

3. Safety management of hoisting operations

Inspection of lifting equipment and rigging: Before hoisting, check whether the crane's wire ropes, hooks, pulleys and other components are intact, and whether the rigging specifications and strength meet the hoisting requirements to ensure that there are no defects such as fracture and deformation. When lifting heavy objects such as glass, use special lifting tools to avoid heavy objects falling due to improper binding.

Hoisting process control: The hoisting operation needs to be commanded by a special person, the command signal should be clear and unified, and the operator should strictly follow the command instructions. A cordon is set up in the lifting area, and irrelevant personnel are strictly prohibited from entering, and there must be no obstacles within the crane's rotation radius. When lifting fragile objects such as glass, it should be lifted smoothly and moved slowly to avoid colliding with other objects and preventing glass from breaking and falling.

Hoisting balance and fixation: ensure that the center of gravity of the lifted heavy object is stable to avoid tilting and swaying during the hoisting process. After the heavy object is hoisted to the designated position, it needs to be temporarily fixed first, and then the spreader should be released after confirming stability to prevent the heavy object from falling and injuring people.

4. Safety protection on the construction site

Temporary electricity safety: The temporary electricity consumption on the construction site must comply with the "Technical Specifications for the Safety of Temporary Electricity on the Construction Site", set up a special distribution box, implement the "one machine, one gate, one leak, one box" system, and match the parameters of the leakage protector. Wires and cables need to be protected overhead or through pipes to avoid being crushed and worn, and it is strictly forbidden to connect wires indiscriminately. When using electrical equipment, operators need to wear insulated gloves and insulated shoes, and regularly check the insulation performance of electrical equipment.

Fire and explosion-proof management: Smoking is strictly prohibited at the construction site, and obvious non-smoking signs are set up. During welding and cutting operations, clean up the surrounding flammable materials, equip fire extinguishing equipment (such as fire extinguishers, fire buckets, etc.), and inspect the site after the operation is completed to confirm that there is no fire hazard before leaving. Flammable and explosive items such as oxygen cylinders and acetylene bottles should be stored separately at a distance of not less than 5 meters and a distance of not less than 10 meters from open flames, and safety operating procedures should be strictly followed when used.

Object strike prevention: Construction personnel must wear safety helmets when working, and materials and tools on the construction site should be stacked neatly to avoid throwing materials from high altitudes. Debris should not be stacked on the edge of the floor or scaffolding to prevent objects from falling and injuring people. A safety protection shed is set up under the construction area, which adopts double-layer protection and can effectively block falling objects.

5. Safety supervision of the construction process

On-site inspection and hidden danger investigation: Arrange full-time safety officers to conduct uninterrupted inspections of the construction site, focusing on the implementation of safety measures in key links such as high-altitude operations, hoisting operations, and temporary electricity use. For the potential safety hazards found, immediately issue a rectification notice, clarify the person responsible for the rectification, the rectification period, track the rectification situation, and continue the construction after the rectification is qualified.