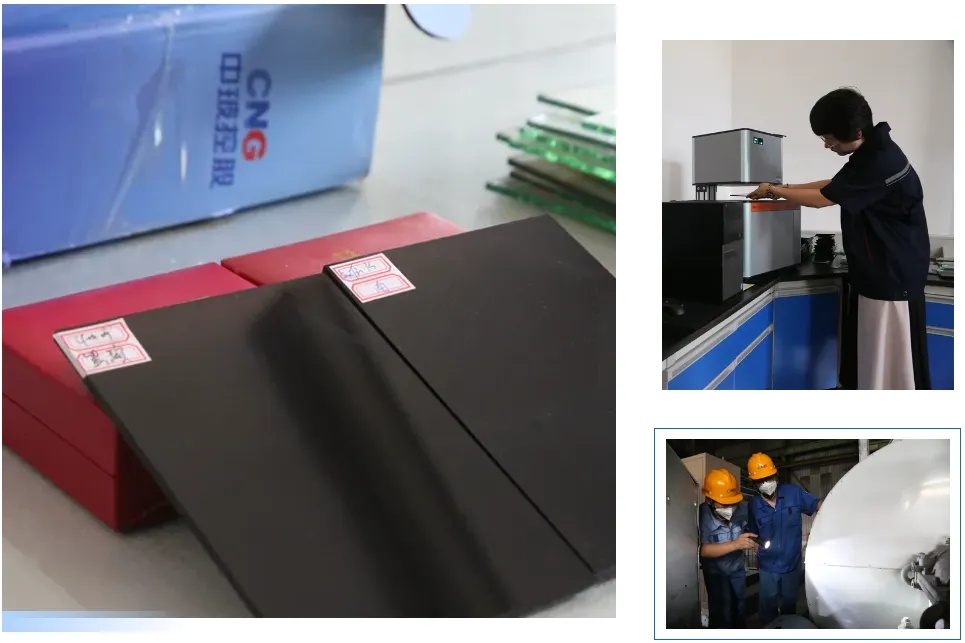

Recently, in the Weihai China Glass sample room, R&D engineer Qiu Shanshan is placing a newly listed privacy black glass sample on the testing equipment, and with the continuous rolling of the detection data, the detection data such as the direct transmittance ratio of sunlight, visible light transmittance ratio, and photo-heat ratio are clear at a glance.

Through the testing data, the outstanding performance of this black glass in various performance indicators emerged one by one - it not only has low light transmittance, but also has good weather resistance, high strength and light weight, and truly integrates beauty and practicality.

Since the laboratory sample production in 2019, Weihai China Glass has been paying close attention to the research and development and production of black glass. "We initially carried out laboratory sample production for the company's own technology accumulation. After the laboratory sample was successfully produced, it was not mass-produced. Qiu Shanshan said that this year, Weihai China Glass decided to put black glass into the market, and black glass technology has moved from the laboratory to a new stage of market application.

But mass production is not simply scaled up in equal proportions. In this process, there are a series of process problems that need to be solved. Qiu Shanshan introduced: "The conditions of our kilns and laboratories are different, so we need to reduce the iron content, add different pigments, and constantly adjust the ratio to find a more suitable technical route. ”

The solution of process problems is the undertaking of R&D results in the production process. After 3 months of multiple trials and optimizations, Weihai China Glass's privacy black glass finally achieved mass production and listing, bringing new growth points to the company's development.

With innovative research and development and differentiated market development, Weihai China Glass's products have not only become "sought-after goods" in the industrial chain, but also set off an innovation boom in building materials and other industries. After the launch of privacy black glass, the products are exported to domestic and foreign markets, and the current production plan has been scheduled until the end of August.

This is not an isolated new product that has brought great changes to the industry. Over the years, Weihai China Glass's R&D team has been deeply involved in glass functional innovation, and has successfully launched dozens of special products such as online Low-E glass, online TCO glass, and online sunlight control easy-to-clean glass.

High-end products are inseparable from strong production lines. In recent years, Weihai China Glass has invested 270 million yuan to carry out intelligent transformation of three production lines. Nowadays, the CNC automation rate of the workshop exceeds 95%, and the total operating cost is reduced by 25%, driving the production capacity to jump. Taking the float glass production line as an example, the thickness measurement is completed in 3 seconds, the precise cutting is completed in 5 seconds, and the whole process from production to packaging is completed in less than 1 minute. "We have 3 production lines with a daily output of about 27,000 heavy containers." Kuai Xiujie, director of the second line workshop of Weihai Zhongli Float Method, said.

High precision and high efficiency production capacity have given products a broad market. "In the first half of this year, the sales volume of all our products increased by 75% year-on-year, and export sales increased by 112% compared with the same period last year. We will continue to develop new customers, adhere to the two-legged walk at home and abroad, and constantly adapt to the new prospects of market development." Liu Wenting, head of the international business section of Weihai China Glass Sales Department, said that the recognition of the domestic and foreign markets gives them the confidence to invest in the research and development of next-generation glass technology, forming a virtuous circle of "good products-market-re-research and development".

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China