Abstract:This paper introduces the design of the construction measures for the large ceiling at the T3 corridor position of the "Yinglan International Financial Center" project, and customizes the construction measures of a super high-rise suspended mobile platform for the installation of aluminum plates and keels of the aerial corridor with a construction height of 140 meters and a span of up to 60 meters, which perfectly meets the construction and installation requirements of such special structures. It provides an effective example for the construction of super high-rise large ceilings.

Keywords: suspended platform; super high-rise aerial work; Construction

1 Introduction

Proudly located in Xiamen's new waterfront financial district, Yinglan International Finance Centre is a comprisal of three towers of offices, serviced apartments, a luxury hotel, retail and dining space, and seamless connectivity to an adjacent subway station.

This multi-functional building creates a convenient and rich life scene for people. Looking at Yinglan International from a distance, the overall building presents a shocking "gate" shape, with four skyscrapers reaching into the sky, and a giant "door beam" lying in it, closely connecting the two buildings in the middle, outlining the magnificent landscape of the "gate of the building", which deserves to become a landmark building in Xiamen's emerging financial district.

Among them, the T3 corridor, as the finishing touch of the project, occupies a key position in both architectural aesthetics and construction technology. During the construction process, a series of international cutting-edge technologies such as cantilever method, hydraulic overall lifting, and high-altitude secondary lifting have been applied.

The total weight of the steel structure in the conjoined area is 5,342 tons, the lifting height of the corridor is 140 meters, and the maximum span of the corridor is 60 meters.

The birth of Yinglan International Financial Center not only shows the artistic charm of modern architecture to the fullest, but also injects strong impetus into Xiamen's urban development and enhances the city's image. Its unique "gate" shape carries the meaning of openness and inclusiveness, and deeply interprets the unique urban cultural connotation of Xiamen.

2. The design background of the high-altitude suspension construction platform

The construction of the high-altitude ceiling of the Blue International Financial Center faced many challenges. The steel structure of the door beam is an aluminum veneer ceiling below, and it is difficult for conventional construction measures to meet the installation needs. This is because the aluminum veneer ceiling has high requirements for the construction process, and the area is at a high altitude, the location is special, and the construction safety and technical difficulty are great.

Judging from the actual situation on site, the system is located at the bottom of the T3 corridor, with an elevation of about 134.8M (30F). The ceiling aluminum plate is made of open, outdoor fluorocarbon spraying treatment of 3mm aluminum plate vertical seam width 4mm, transverse seam width 4mm, internal 2mm thick silver white oxide aluminum plate for waterproofing, due to the overall lifting of the general package corridor, the ceiling is divided into 2 stages of construction, the overall lifting of the corridor before the construction of the lifting area keel, the remaining part of the construction after the completion of the ceiling lifting.

To carry out ceiling construction in such a high-altitude position, it is necessary not only to consider the stability of the structure, but also to solve the problems of limited construction operation space and difficult material transportation. Traditional construction methods could not meet the construction requirements of the area, which required an innovative construction technology.

In order to ensure the safety and quality of construction, it is necessary to adopt special construction technology and equipment, and formulate detailed construction plans and safety measures to ensure the safety of personnel and equipment during the construction process.

3. Construction technical difficulties and solutions

3.1 Technical difficulties

3.1.1 Risk of working at height

Working at an altitude of 140 meters is extremely difficult to ensure the safety of personnel. At this height, in the event of an accident, the risk of falling is high, and the safety of personnel is greatly threatened. At the same time, the environment of high-altitude work is complex, and factors such as wind load and temperature changes also increase the difficulty of operation. For example, in the Yinglan International Financial Center project, the complex environment of strong wind belts has brought many challenges to high-altitude work due to the influence of subtropical oceanic monsoon climate.

3.1.2 High hoisting accuracy requirements

The connection part of the steel structure of the door beam is complex, and the hoisting position and angle need to be accurately controlled. The connection between the steel column and the steel beam, the splicing between the steel beam and the steel beam, etc., all require high-precision operation. For example, the hoisting of the T3 corridor has a complex structure, and the connection accuracy between the components needs to be ensured during the hoisting process, otherwise the stability and safety of the overall structure will be affected.

3.2 Solutions

Considering the difficulty of the measures to build the ceiling in the later stage and the difficulty of installing the aluminum plate, through the analysis of the installation space of the height of this position of the project, it is finally determined that the installation work of the aluminum plate and the keel in the later stage is solved by adopting the construction scheme of the suspended platform.

3.2.1 Installation of ceiling keel

According to the general contracting plan, the steel structure of the corridor is hoisted as a whole, but due to the limitation of the main structure, the lifting part is the central area, and when the steel structure is pre-lifted to 1.7 meters on the ground, our company completes the installation of the window cleaning machine track and aluminum plate keel in this area on the ground.

Basic conditions for the installation of the top aluminum plate: check whether the basic conditions for the installation of the aluminum plate on the ceiling are met. And the external dimensions of the aluminum plate part of the ceiling installed in the building are reviewed, and the allowable deviation range of the matching size with the aluminum plate of the ceiling is required

Material inspection: check whether the variety, specification and color of the ceiling keel and aluminum plate are in line with the design; Whether the aluminum plate of the ceiling is damaged, deformed, scratched and polluted during transportation, etc. Unqualified ceiling aluminum plates shall not be installed.

Personnel preparation: During the installation of the ceiling, 2 groups of people are arranged for 12 people to work at the same time.

3.2.2 The setting of the platform rail

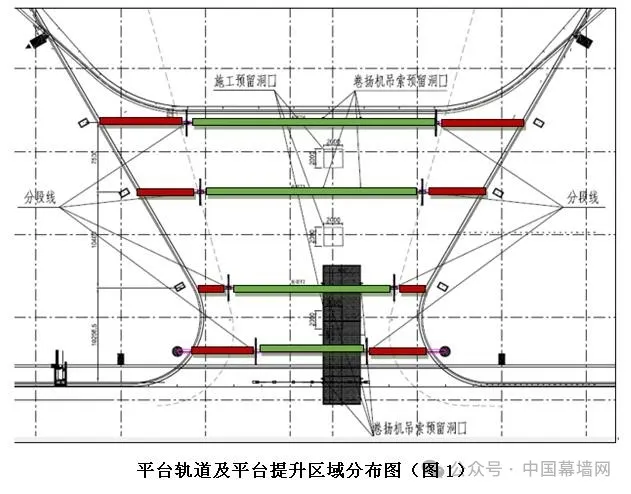

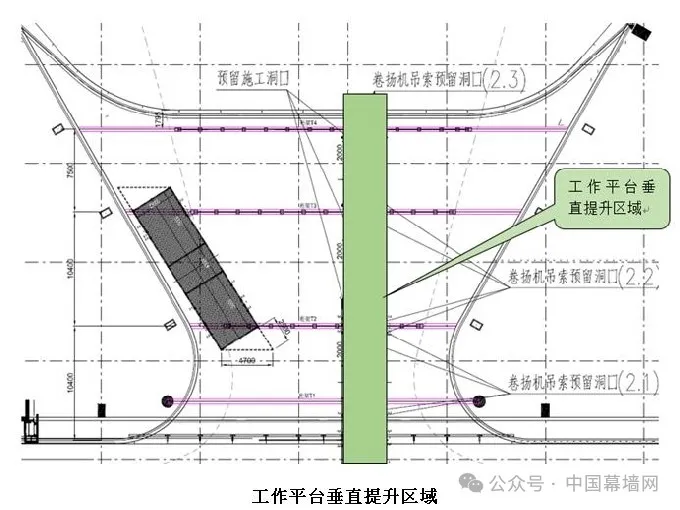

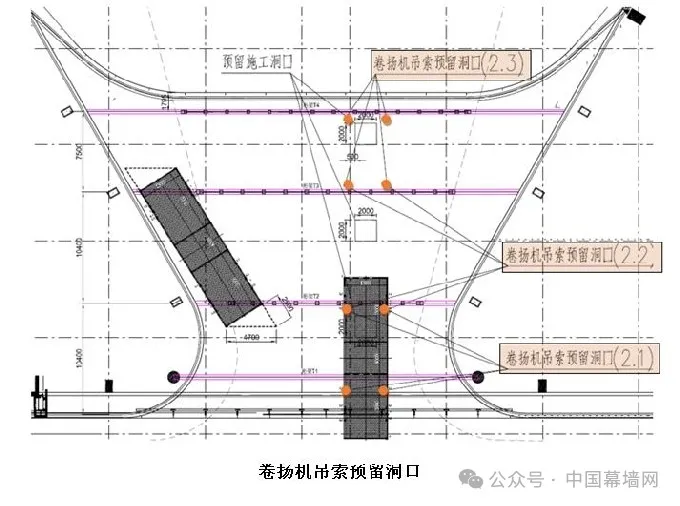

First of all, the setting of the platform guide rail, 4 rows of platform guide rails (green part) are arranged in the middle area below the steel structure of the air corridor, and 8 side guide rails (red area) are arranged at the side to realize the installation of the middle standard panel and the closing panel respectively.

3.2.3 Two-part platform track processing scheme

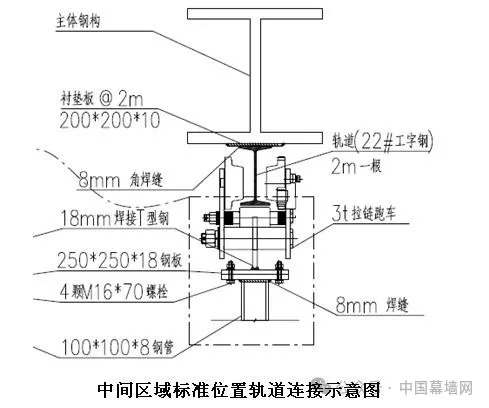

The guide rail platform in the middle area is the ground welded installation part (green part in Figure 1 below), the track is composed of 2m long 22# I-beam, the track is welded on the main steel structure, and the fillet weld is 8mm (Figure 2). Welding is completed on the ground before the main truss is lifted as a whole.

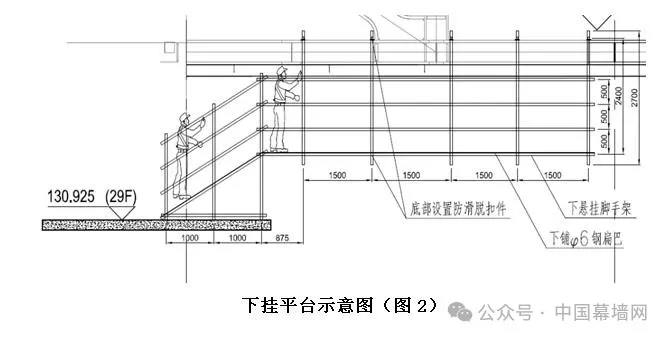

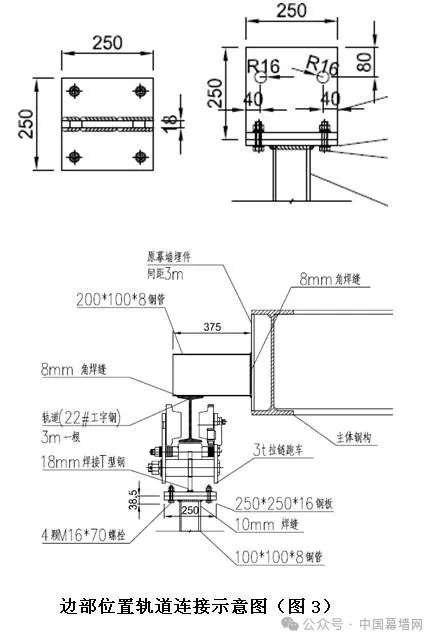

The special position platform rail at the side is the aerial welded installation part (the red part of Figure 1 below), and the working face of this part is installed using the lower suspension scaffold platform (Figure 2 below). The track is 3m long and 22#工字钢组成, and the track is welded to the main steel structure with a fillet weld of 8mm (Fig. 3). After the main body truss is lifted, the anti-hanging scaffold is used as a working platform to weld and install the side rail.

Hoist: The overall weight of the platform is less than 5T, so the lifting of each platform selects 4 3T winches for the overall lifting operation.

Wire rope: 6x19-1960 rigid core Φ16

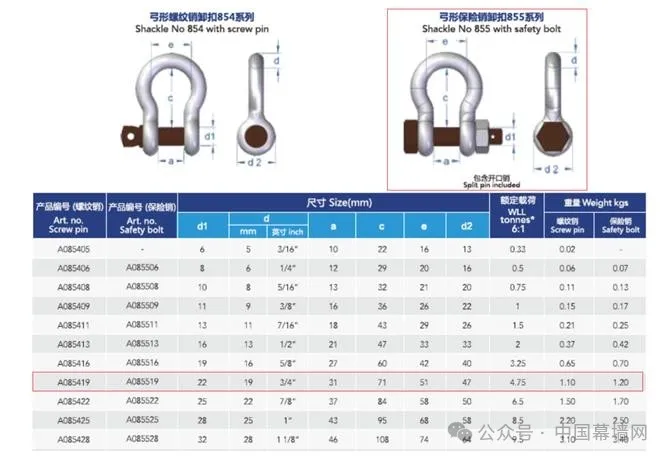

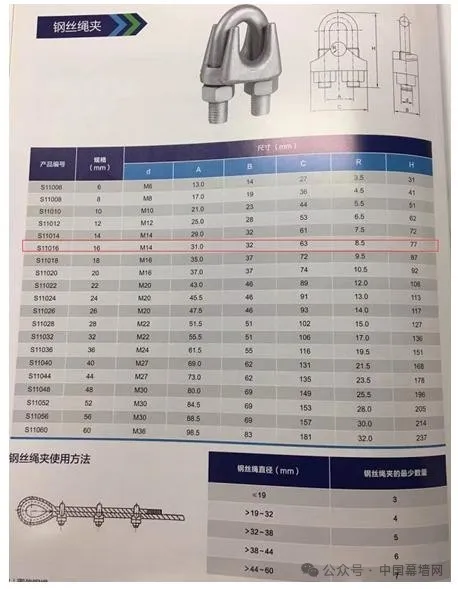

Shackles: A085419 rated load 4.75t, 8 on the platform, 8 on the pulley.

Luge: HQG1-32 rated load 5t, a total of 8.

Wire rope clamp: S11016 Each wire rope is equipped with at least 3 pieces. 8 sets of winch equipment, with at least 24 sets.

3.2.5 Lifting and layout of mobile platforms

The lifting of the mobile platform is a key step in the overall installation process and a major source of danger. In order to achieve a safe and stable lifting platform, it is necessary to make full preparations and organize the work before lifting.

3.2.5.1 Setting of lifting point

The whole system is equipped with 4 platform tracks, 3 mobile working platforms, 8 winch lifting rope points, and each working platform is equipped with 4 lifting points. The platform lifting position is set in the middle position (see figure below).

PREVIOUS:Ukraine and South Korea join forces to lay out the glass manufacturing industry! NEXT:Analysis of future glass price trend Downstream demand is gradually recovering

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China