At the same time, with the improvement of materials and processes, the watertightness and airtightness of the curtain wall, as well as the ability to resist the invasion of various natural external forces (such as typhoons, earthquakes, high temperatures), reduce the impact of thermophysical factors (heat radiation, condensation), and also include the improvement of comprehensive performance such as sound insulation and fire prevention.

Today's curtain walls are widely used in the exterior walls of various buildings such as airports, transportation hubs, stadiums, museums, convention and exhibition centers, cultural centers, corporate headquarters, office buildings, large hotels, and shopping malls.

In order to help industry readers establish a systematic and comprehensive "curtain wall structure" knowledge system, the article will share from "curtain wall structure classification and characteristics" to "performance".

1. Definition and classification of curtain wall

1. Definition

The curtain wall is the outer wall enclosure of the building, does not bear the load of the main structure, and is a lightweight wall with decorative effects, which is composed of structural frame and inlaid plates, and the curtain wall has a certain micro-movement ability in the plane relative to the main structure.

The basic functions of curtain walls: thermal insulation, sound insulation, wind and rain protection, reducing the weight of the wall, and meeting the requirements of decorative effects;

The first project in our country to adopt a glass curtain wall was the Great Wall Hotel in Beijing built in 1984.

2. According to the construction process:

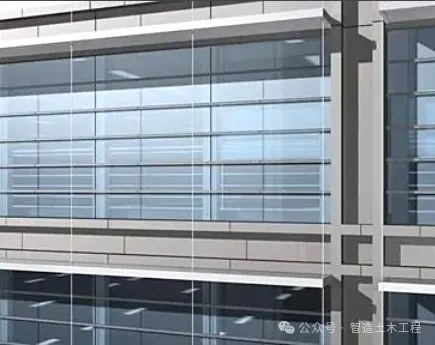

Component type (frame type): Frame support curtain wall (commonly known as bulk) of columns, beams and panels installed on site in turn.

Unit type: The panels and metal frames (columns, beams) are assembled into curtain wall units in the factory, and the frame supports the glass curtain wall in the form of curtain wall units to complete the installation and construction on site.

3. According to the type of panel:

Glass curtain wall: single-layer glass, insulating glass, laminated (laminated, wire-cladded) glass, etc.

Metal Sheet Curtain Wall: Single-layer Aluminum Plate, Composite Aluminum Plate, Honeycomb Aluminum Plate, Stainless Steel Plate, Color Steel Plate, Titanium Alloy Plate, Copper Plate.

Other materials curtain wall: terracotta board, porcelain board, microcrystalline stone, Qiansi board, clear water concrete board

Microcrystalline glass curtain wall

4. Introduction of component curtain wall

(1) The main feature of the component curtain wall: all supporting structural materials are transported to the construction site in loose parts and installed at the construction site in turn. It is currently the largest production scale on the market and the most mature traditional curtain wall.

(2) According to the different forms of the external structure of the panel, it can be subdivided into: 1. Hidden frame curtain wall; 2. Semi-hidden frame curtain wall (a. horizontal and vertical b. horizontal and vertical); 3. Open frame curtain wall;

(3) Advantages of component curtain wall: 1. Mature process and low construction difficulty; 2. Relative to the curtain wall of the unit, the cost is low; 3. Easy to disassemble, easy to replace, easy to maintain;

(4) Disadvantages of component curtain wall: 1. Manual error in on-site construction is unavoidable; 2. The quality of silicone sealant is affected by rain and temperature; 3. The probability of water seepage in single-channel seals is high; 4. Occupying a large construction site (processing plant, material warehouse, etc.); 5. Compared with the unit curtain wall, the installation speed is slow, and the on-site construction labor investment is large.

Horizontally bright and vertically hidden

Horizontally hidden and vertically bright

2. The main performance indicators of the curtain wall

The main design performance indicators of glass curtain walls:

(1) Wind pressure resistance

It refers to the ability of the building curtain wall to maintain normal performance without any damage under the action of wind pressure perpendicular to it, specifically to ensure the strength and stiffness of the curtain wall, and its measurement index is the standard value of wind load.

(2) Watertightness

It refers to the ability of the curtain wall to prevent rainwater leakage under the simultaneous action of wind and rain. According to different climatic conditions, we take the indoor and outdoor air pressure difference as the measurement index of the curtain wall's rainwater leakage prevention performance under the premise of ensuring that the curtain wall does not leak rainwater, and formulate grading standards according to the fixed part and the opening part of the curtain wall.

(3) Air tightness

Under the action of wind pressure, when the opening part is closed, it prevents air from passing through the curtain wall.

(4) In-plane deformation ability

The curtain wall is all structured to maintain the performance of the curtain wall after the deformation of the building is forced by the displacement between the floors. and wind pressure resistance, air tightness and water tightness are called the "four characteristics" of curtain walls.

(5) Sound insulation performance

As the outer envelope structure of the building, the sound insulation performance of the curtain wall is directly related to the quality of the indoor acoustic environment, especially in noise-sensitive areas such as traffic arteries, airports, and commercial areas.

Curtain wall sound insulation is a systematic project, which needs to be controlled from the four dimensions of material selection, structural design, construction accuracy, and later maintenance. In noise-resistant buildings, the core strategy of "laminated glass + hollow composite + seal strengthening" is generally adopted, combined with the iterative optimization of on-site measured data, to achieve the dual excellence of acoustic environment and architectural aesthetics.

(6) Impact resistance.

The ability of the curtain wall to resist outdoor impacts such as flying objects and birds in hail and strong winds, as well as the impact of indoor people and objects.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China