The project plan includes innovative industrial buildings, commercial and living facilities, science and technology exhibition halls, data and intelligent control centers, etc., and will be built into a super headquarters with a leading role in global radiation in the future, creating a 100-billion-level industrial cluster.

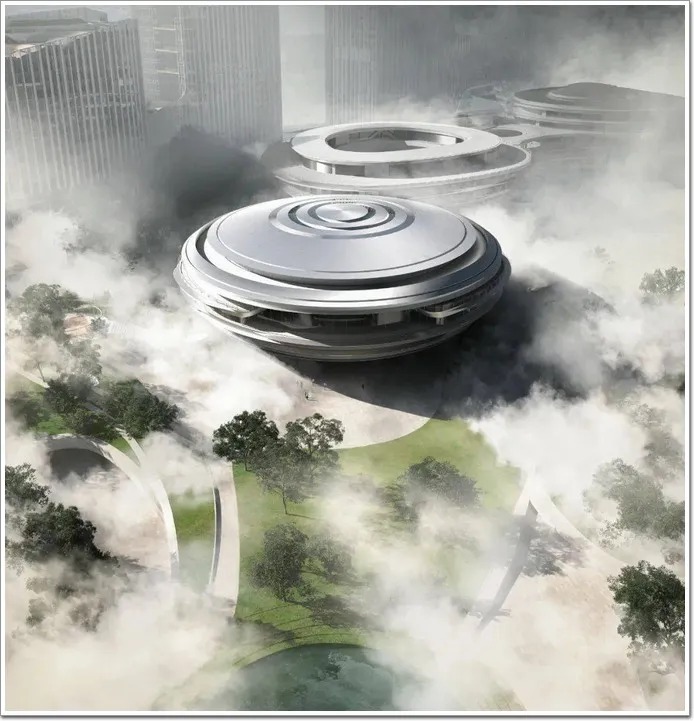

Design concept: The overall design of this project is an irregular oval flying saucer, and the building will overhead the ground floor, so that it floats on the ground, showing a flowing posture. The weather is cloudy and mist, floating in the clouds, more beautiful than a cloud tower.

The façade is crowned with soft curves, curved oversized ribless glass, and cantilevered metal wings with curved gradients, making the curtain wall light and agile.

Curtain wall design characteristics: In addition to the unique shape, this project has outstanding highlights in curtain wall system design, digitalization, visualization, new technology, and new material application.

The interlayer metal plate flying wing modeling system adopts prefabricated design, three-dimensional adjustable design, and transverse core plugging design to ensure the smooth connection of adjacent modules and smooth overall shape.

The façade is an ultra-high ribless all-glass system, using multi-layer angle hollow and ultra-thick glass, with a maximum specification of 8900mm in height and 3000mm in width and a weight of 5 tons. In terms of node design, special aluminum alloy grooves are set at the bottom to meet micro-angle adaptability, high space perspective and safety.

The ceiling adopts a honeycomb stainless steel plate insertion system to enhance the flatness of the panel.

The 8 roofs adopt a new material ETFE membrane system, ETFE has the advantages of fire protection, heat insulation, rainwater self-cleaning, durability, heat composite processing, etc., and its plasticity characteristics make its grid size almost unlimited, which can adapt to various complex shapes of curved surfaces, and the roof shape of this project echoes the entire flying saucer shape.

In the design stage, the shape of the flying wing modeling line is optimized and analyzed by 3D modeling technology and BIM technology. The design team uses BIM to model profiled components, enabling one-click automatic numbering, material picking, and process generation, ensuring precision and accuracy in design.

The project team perfectly transformed the design concept into reality through innovative design and the application of new materials, new technologies and new processes. During the construction of the project, Fangda Jianke won honors such as "Excellent Partner" and SVP Excellence Award.

This cloud building "suspended" on the ground will become an important landmark of Shenzhen's "Internet +" future science and technology city, injecting new vitality into the development of the Guangdong-Hong Kong-Macao Greater Bay Area.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China