【Abstract】In this study, a large number of test data were collected through the deformation test of glass, the comparison of different glass reflection images, the continuous monitoring of internal pressure and temperature of the hollow layer of insulating glass, and the continuous monitoring of atmospheric pressure and temperature. According to the derived equations, the real causes of various distortion phenomena in architectural glass reflection images are interpreted. A new scheme for glass deformation testing and a direction for controlling image distortion are proposed.

Keywords: glass image, distortion, temperature, equation

One. preface

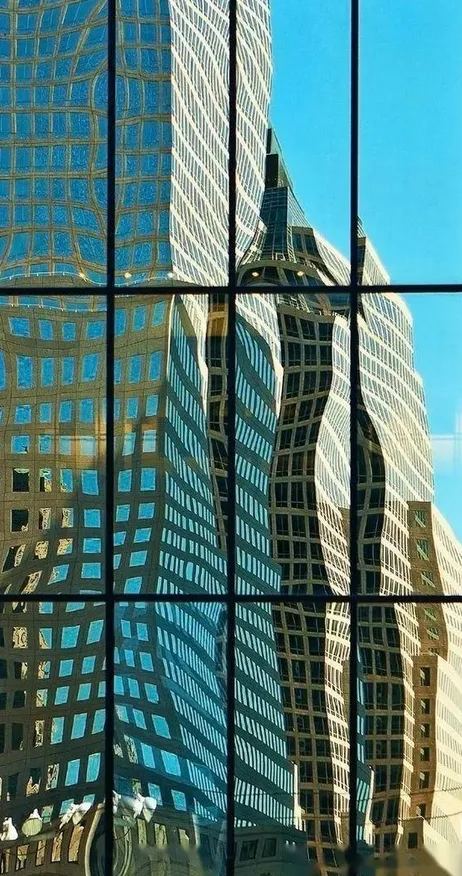

Glass curtain wall has been widely used in modern buildings with its beautiful and energy-saving characteristics, glass curtain wall can be seen almost everywhere in modern cities, however, you often find that the glass curtain wall reflects the architectural image is distorted and deformed, and the good end of the building appears ugly in the "eyes" of the glass curtain wall. There have been a lot of analyses on the causes of glass image distortion, however, most of the previous analyses have only been qualitatively described.

In this paper, an optical analysis model is established for the first time through a large number of observations, tests and experimental monitoring data, and the glass image distortion equation is derived, and the derived equation is successfully used to interpret the glass image distortion.

However, due to the many factors that can cause image distortion, people often cannot distinguish which factors cause the distortion of the image, which is why people often cannot clearly explain how the distortion is caused in the face of image distortion.

In order to explore the real cause of glass image distortion, the author has conducted a large number of experiments.

Two.Research on deformation caused by tempering:

The glass commonly used on building curtain walls is tempered glass or semi-tempered glass, and tempering is the process of secondary heat treatment of the original sheet. As we all know, glass will be deformed after tempering, GB 15763.2-2005 "Safety glass for construction - Part 2 tempered glass" stipulates the curvature of flat tempered glass, requiring that the bow bend should not exceed 0.3%, and the waveform bending degree should not exceed 0.2%. In order to truly understand the deformation degree of tempered glass, we entrusted the National Construction Engineering Quality Supervision and Inspection Center to do the following four tests, which are carried out according to GB15763.2-2005:

1. The insulating glass is peeled off from the single glass for bending detection

2. On-site testing of the curvature of hollow tempered glass on the wall

3. Comparison of the plane curvature detection data of the finished hollow tempered glass under the two conditions of wall and flooring

4. Comparison of the flat curvature test data of the hollow tempered glass on the upper wall and the single piece of tempered glass in the peeling and referral laboratory

The following are the details of the trial:

1. The insulating glass peeling surface glass is sent to the laboratory for the testing of the flat bending of a single piece of tempered glass

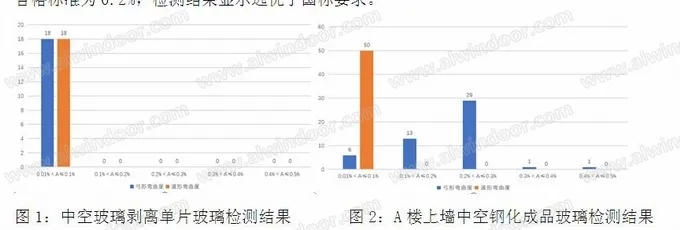

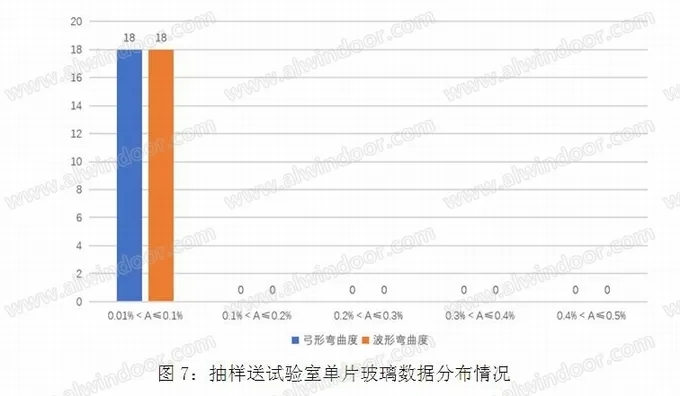

A total of 18 pieces of glass were extracted and sent to the laboratory for the bending test of a single piece of tempered glass, and the glass configuration was 6mm+12Ar+6mm+12Ar+6mm; The test showed that all the tested glass was qualified, of which the data level detected by the bow bending value was 0.01%-0.05%, and the qualification standard was 0.3%; The data level detected by the waveform bending value is 0.01%-0.05%, and the qualification standard is 0.2%, and the test results show that it is far better than the national standard requirements.

2. On-site inspection of the flat curvature of hollow tempered glass on the upper wall

A total of 76 pieces of hollow tempered glass were extracted in two batches for plane bending testing, and the glass configuration was sent to the laboratory glass configuration. The data distribution of the bow bending value and waveform curvature value of the two batches are shown in Fig. 2 and Fig. 3, respectively. The test showed that the bow deformation increased, but the waveform deformation did not change much, indicating that the deformation increased after the insulating glass was closed.

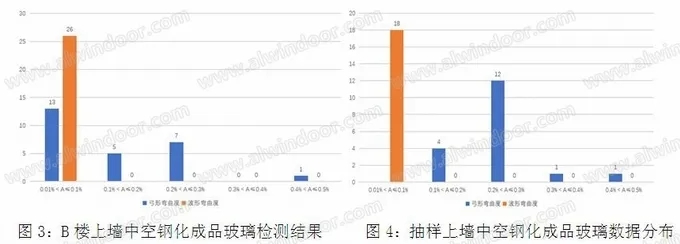

3. Horizontal comparison and analysis of the bending data of the plane bending of the finished hollow tempered glass under the two conditions of wall and flooring

Eighteen pieces of hollow tempered finished glass were extracted on site for this comparative analysis to verify whether the cold bending deformation effect on the glass during the construction process was greatly affected. The data distribution of the detection is shown in Figures 4 and 5.

From the above data distribution, it can be seen that there is no significant difference between the flat curvature of the finished glass on the upper wall and the floor, which proves that the plane curvature of the glass is not significantly affected during the construction process.

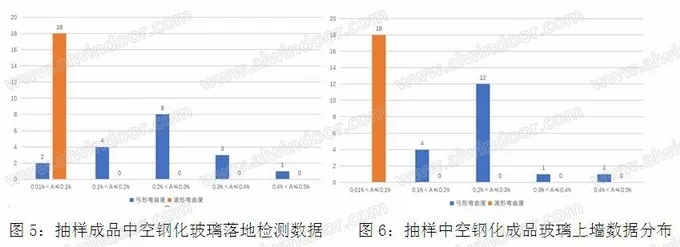

4. Comparative analysis of the level of the flat bending detection data of the finished hollow tempered glass and the single piece of tempered glass sent to the laboratory after the wall is put on the wall

A total of 18 pieces of hollow tempered glass were extracted for this comparative analysis to verify the influence of the air pressure difference inside and outside the hollow cavity on the curvature of the glass plane, resulting in the degree of glass image deformation. The data distribution of the detection is shown in Fig. 6 and Fig. 7.

From the above data distribution, it can be seen that the bow value of hollow tempered finished glass is much greater than the bow value of a single piece of tempered glass peeled off from the same piece of glass, and the two are not on the same order of magnitude at all, and the bow value of finished glass is between 10 to 20 times the value of a single piece of glass, and can even reach 30-40 times. In order to further confirm whether this is the main reason, we will pull the stripped single piece of tempered glass back for installation, and compare the image effect and find that the image effect of the single piece of glass is much better than that of the finished glass, which shows that the bow deformation of the finished tempered insulating glass will cause serious distortion of the reflection image, see Figure 8 below

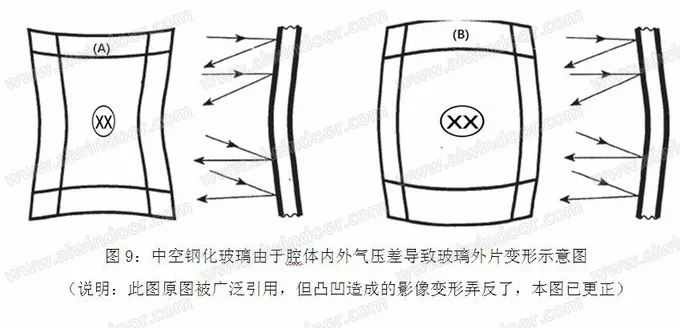

Through the comparison of the above data and the corresponding images, it can be seen that the main reason for the serious deformation of the on-site glass reflection image is the increase of the bow bending degree of the outer glass (convex or concave) due to the difference between the internal and external air pressure of the hollow cavity. Insulating glass is a closed system, when the internal pressure changes, the pressure will act on the glass surface, which will cause the expansion or contraction of the glass to deform; When the air pressure changes, if the air pressure in the insulating glass cavity is lower than the external atmospheric pressure, the insulating glass will shrink and deform; If the air pressure in the insulating glass cavity is higher than the external atmospheric pressure, the insulating glass will expand and deform, resulting in the formation of the so-called concave and convex mirror "haha mirror" phenomenon of the on-site glass. As shown in Figure 9. According to the ideal gas equation: pV=nRT, when the temperature changes, the internal volume and pressure of the insulating glass will change, but the change of internal pressure is not only caused by temperature, which will be further explained later.

threeInsulating glass internal pressure and image deformation test:

Through the above experiments, we can speculate that the change of pressure inside the insulating glass leads to the change of glass image, and in order to further explore the influence of pressure change on image distortion, we have studied the relationship between pressure and deformation in our self-developed "glass image expert system". The system includes a pressurization and decompression host and data logging/control software for remote pressure control.

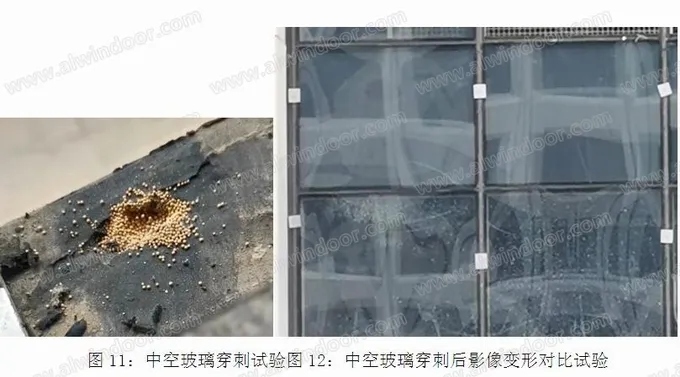

When the insulating glass sealant and spacer are drilled, the molecular sieve gushes out (Fig. 11), showing that there is a large internal pressure in the insulating glass air layer. The glass in the upper right corner of the figure below has been deflated, and the remaining three pieces have not been deflated, and the image distortion has been significantly improved after deflating (Fig. 12).

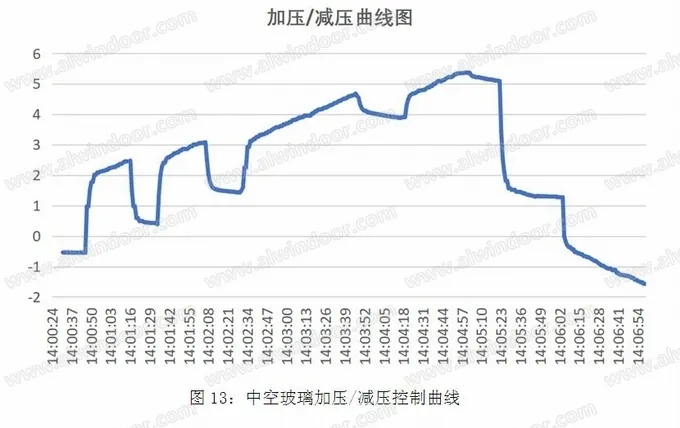

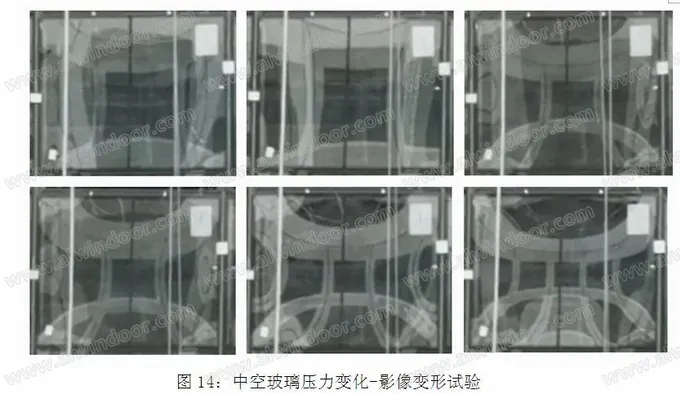

During the test process, the "glass image expert system" was used to remotely control the pressure reduction of the hollow layer of insulating glass (Fig. 13 is the pressurization and decompression curve), and the pressure data was recorded, and the glass reflection image was recorded by video. During the test, it was observed that the glass image changed significantly with the change of air pressure (Fig. 14).

It is worth noting that the glass configuration of the test project is 6+12A+6+12A+6 three-glass and two-cavity insulating glass, due to the underlining of the third layer of glass, the reflection of the second layer of glass is more obvious, because in the process of adding and depressurizing, the first and second layers of glass produce opposite deformation of convex and concave at the same time, so the change process of magnifying and shrinking the two images can be observed at the same time.

fourDistortion rate equation derived:

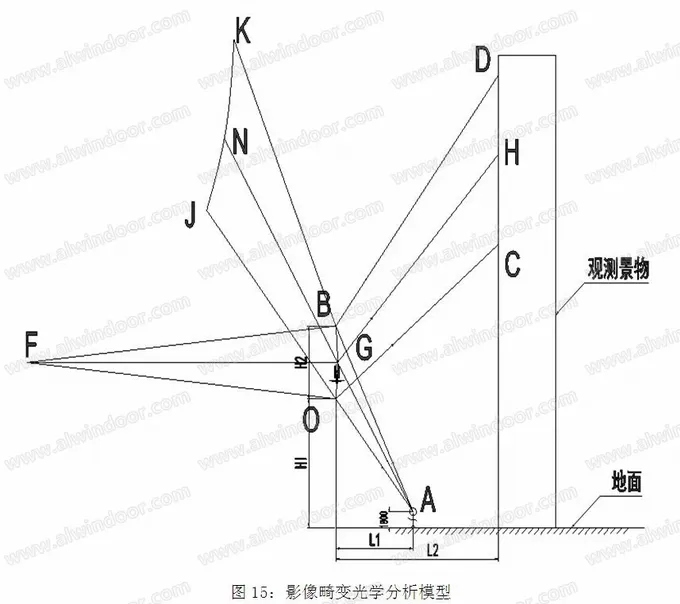

In order to further explore the relationship between deformation and image distortion, we establish an optical model for analysis, as shown in Figure 15:

In Fig. 15, OB is the convex mirror, point F is the center of curvature of the convex mirror, the mirror height is H2, the curved arch height H, the bottom of the mirror is the height from the ground H1, point A is the observation point of the human eye, the observation point of the human eye is 1.8 meters from the ground, the vertical distance from the mirror L1, CHD is the observed building, the vertical distance between the building and the mirror is L2, and the three points C, H and D in the figure are K, N and J in the convex mirror, and the optical analysis shows that the linear CHD image becomes curved KNJ. However, this curve change is not the cause of image distortion, the real reason is the expansion and contraction after DC to KJ imaging.

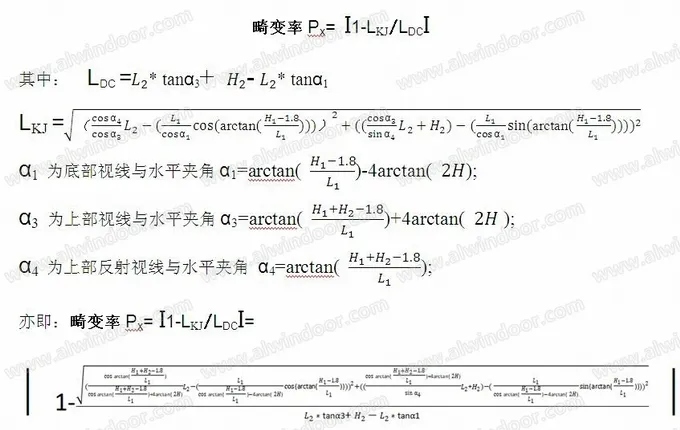

Therefore, we propose the first equation of glass image distortion (distortion rate equation):

Through the calculation of this formula, a series of curves can be obtained, as shown in Figure 16:

PREVIOUS:Decoration dry goods | How to choose Changhong glass? It is enough to pay attention to this! NEXT:Why is semi-tempered glass not safety glass?

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China