Abstract:The design and construction technology research topic of the special-shaped aluminum plate curtain wall project with high difficulty and irregular ultra-limit construction period.

Key words: high-difficulty, irregular and complex modeling aluminum plate; triangular aluminum plate; Spherical glass roof; Three-dimensional twisted splicing members; finite element simulation calculation and analysis of local connectors; 40-day limit; Construction survey positioning

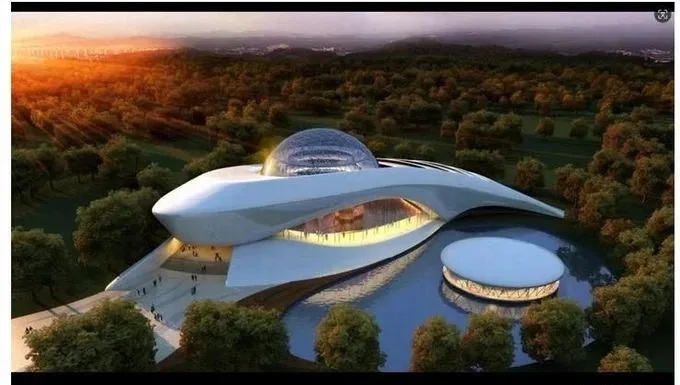

1. The root condition of the project

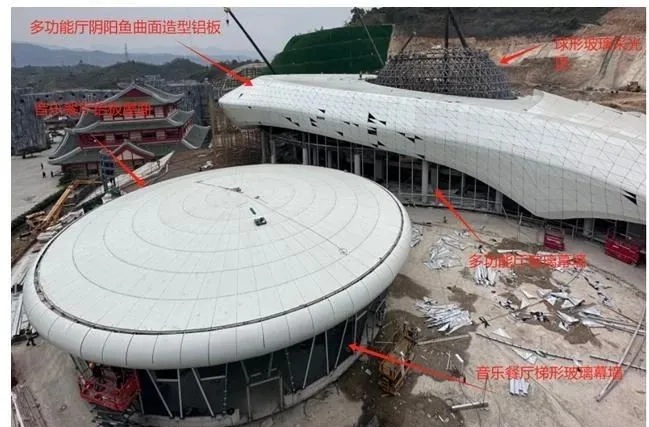

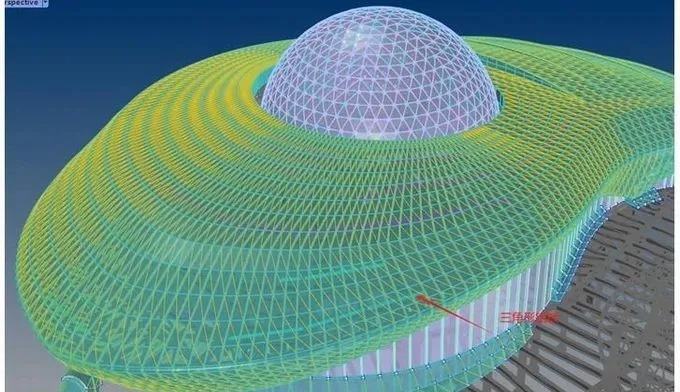

The curtain wall project of Wudang Yimeng 10# floor is divided into two areas: a music restaurant and a multi-functional hall. The music restaurant is composed of a circular aluminum roof and a trapezoidal glass curtain wall, and the multi-function hall is composed of a curved aluminum panel, a glass curtain wall and a spherical glass roof. Among them, the yin and yang fish curved surface shape aluminum plate and spherical glass lighting roof plate are triangular plates, and the use of triangular plates can make the whole curved surface look very smooth and beautiful, which is very suitable for the shape of this project.

2. The technical difficulties of high-difficulty, irregular and complex modeling aluminum plate (design, processing and installation of steel sheet frame).

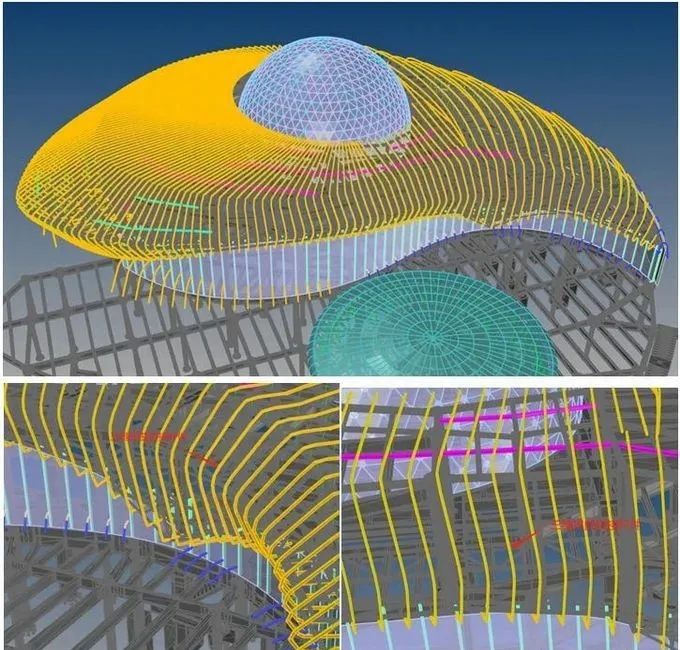

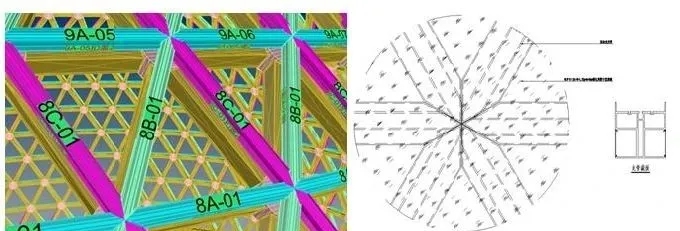

The multi-functional hall of this project Yin Yang fish curved surface modeling aluminum plate, because of its unique appearance modeling, the shape has no rules, and there are great difficulties in the design, processing and installation of the main keel of the aluminum plate. After our design team analyzed the whole modeling, it was finally decided to adopt the design method of 3D twisted splicing rods for the main keel, and the design, processing and installation of 3D twisted splicing rods was a major difficulty in this project. Based on this idea, we modeled the solid solids in detail, and built a construction model with a depth of LOD 400, in which the members could be directly extracted from the machining drawings.

2.1 Design of three-dimensional twisted splicing members

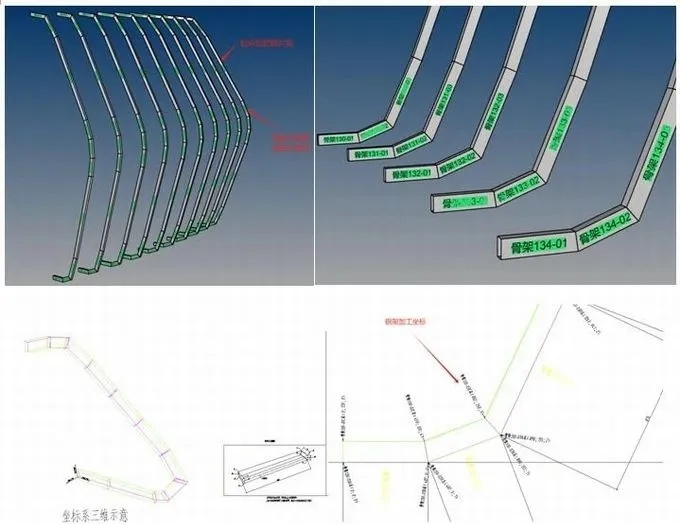

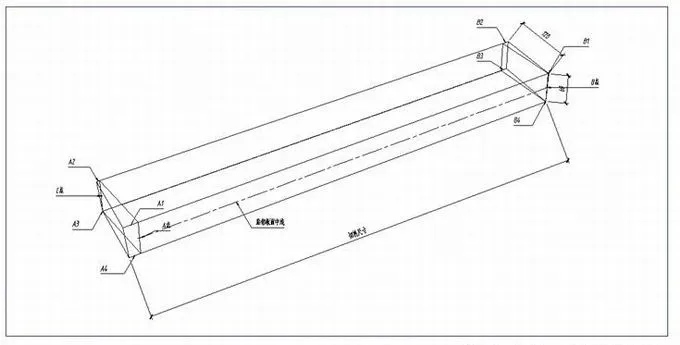

In order to overcome the problem of complex curved surface modeling aluminum plate, the three-dimensional twisted splicing rod is considered to be spliced and processed into a steel plate frame on the ground first, and then the steel plate frame is hoisted, and the length of the steel plate frame is delineated according to the requirements of the site and construction machinery on the site. First, the rods in the construction model are extracted, and the length of the sheet frame is delineated according to the requirements of the site, and the sheet frame is the tailored welding of a section of the square steel pipe of 120*60*4 that is adopted, and the data such as the cutting length, angle and processing coordinates of each section of the steel square pipe are required during ground processing, and the cutting angle is a dihedral angle. There are more than 300 pieces of the whole fish-shaped aluminum plate frame, and there are more than 200 data such as the cutting length, angle, and processing coordinates of each steel plate frame, and each steel plate frame is different. In the face of such a huge design workload, we adopted the rhino GH parametric and programmed design method, and completed more than 70,000 processing data and more than 300 processing drawings of the steel plate frame in the extreme time.

2.2 Triangular aluminum plate panel design

The aluminum plate of the multi-function hall is an irregular curved surface modeling, we have comprehensively analyzed and finally adopted a triangular panel, the triangular panel can adapt well to a variety of irregular curved surfaces, and is easy to process and install, the curved surface effect after forming is very smooth, and the triangular panel is reasonably arranged, making the whole curved aluminum plate modeling texture more beautiful.

2.3 Processing of three-dimensional twisted splicing rods

According to the design and processing drawings and data of the steel sheet frame, the raw materials of the 6-meter 120*60*4 steel square pipe are cut into a section of steel square pipe according to the processing size and angle, and the two ends of the steel square pipe are dihedral angles, and the length and angle of each cut steel square pipe are different, and the accuracy of the angle is high. After the steel pipe is cut, the steel square pipe is placed on the ground according to the steel square pipe number in the steel sheet frame processing model, the angle and coordinates in the plane of the placed steel square pipe are first positioned, and the coordinates outside the plane are positioned through the angle steel bracket when welding, and after the positioning is completed, the splicing part of each section of the steel pipe is fully welded. The welded steel frame needs to be reviewed by the secondary size and coordinates, and the steel plate frame with a large deviation needs to be adjusted to ensure that the specified deviation requirements can be hoisted only if it is finally met.

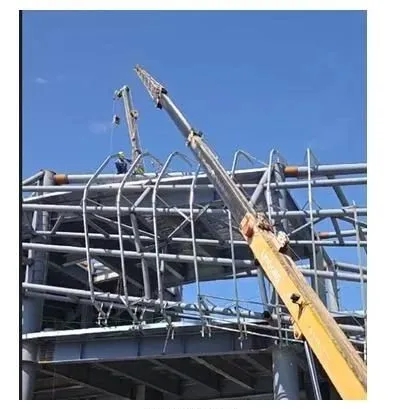

2.4 Hoisting of three-dimensional twisted splicing rods

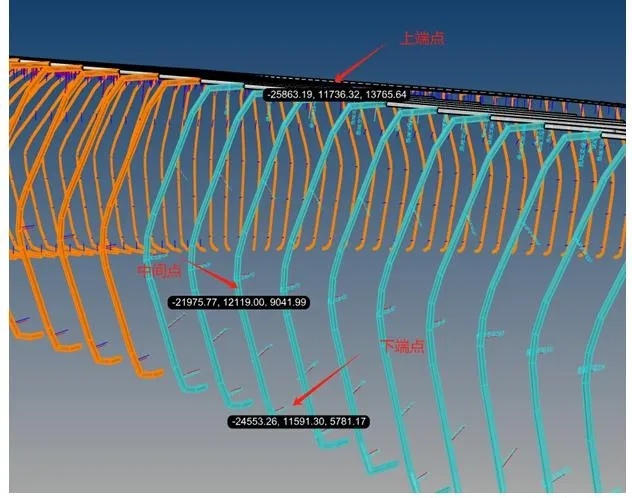

The finished steel sheet frame is also a relatively difficult thing to hoist, the steel sheet frame is welded together by multiple sections of steel square tubes, the length of a steel sheet frame is about 10 meters, it is easy to bend and deform in the process of lifting, and even tear the weld, and the hoisting also needs to be accurately positioned according to the model coordinates; In order to solve the problem of deformation of the steel frame during hoisting, we welded diagonal braces on the steel sheet frame before hoisting, and the diagonal braces were set at the most easily deformed parts, and then dismantled after the hoisting was completed; In terms of the positioning of the steel sheet frame, we use three points of positioning, which are the upper end, middle point and lower end of the steel sheet plus, and the three points are positioned according to the coordinate points in the model, and the steel sheet frame is welded to support the steel square pipe after the positioning is completed.

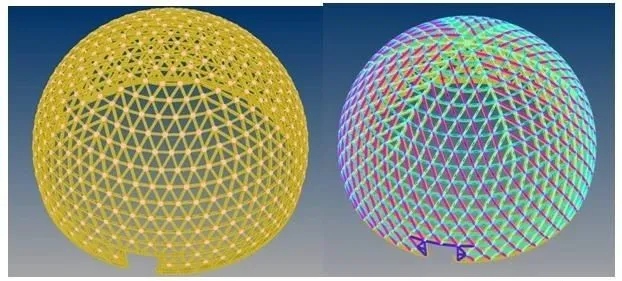

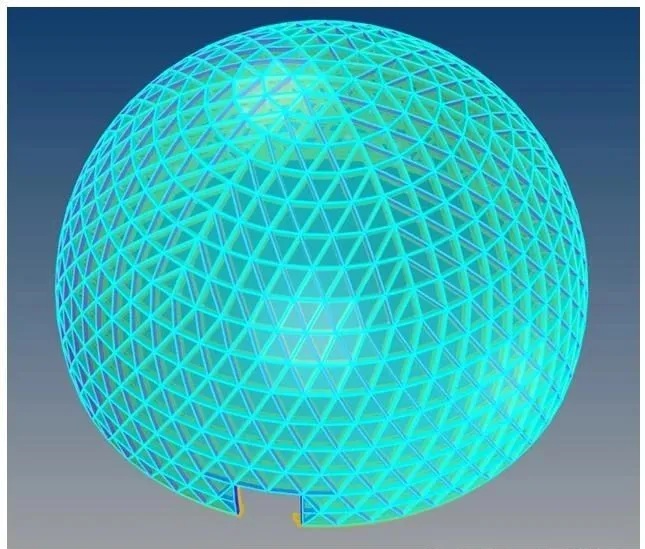

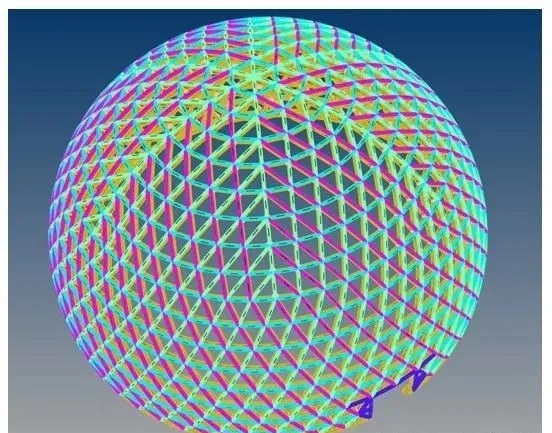

3. The technical difficulties (design, processing and installation) of the spherical glass lighting roof aluminum alloy base

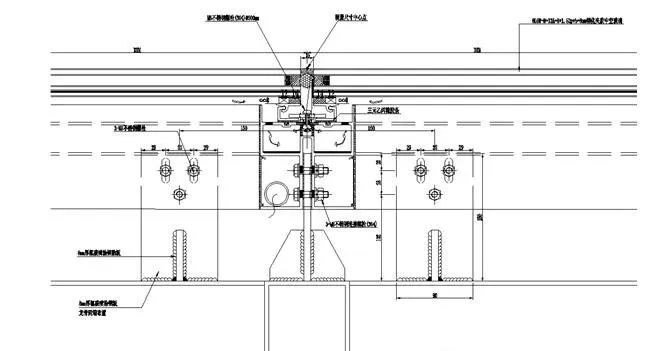

The spherical glass roof is a highlight of the project, the supporting steel structure is a triangular welded assembled steel pipe structure, the steel pipe structure is provided with a layer of aluminum profile keel to support the glass panel, the aluminum profile keel and the steel structure are connected by steel processing parts, and the steel processing parts can be adjusted in both horizontal and vertical directions, so that the deviation problem of the main steel structure can be well solved. The glass panel adopts a triangular panel, and the glass subframe of the panel and the aluminum profile support rod adopts an aluminum profile glass subframe that can adapt to any angle. At the intersection of the joints, six cut angular rods are spliced together, so that the corner parts are tight and beautiful from the interior. When the design of the spherical glass lighting roof also fully considers the collection and discharge of indoor condensate, a drainage groove is set on the aluminum profile rod supporting the panel, and the condensate can be discharged through the drainage groove when the glass has condensate.

3.1 Spherical glass lighting roof aluminum alloy keel design

According to the steel structure model provided by the steel structure company, the coordinates of the intersection node are extracted, the glass surface is established through the coordinates, the glass plate is divided, and the division of the glass plate is consistent with the geometric size of the steel structure. In the rhinoceros model, the edges of the glass plate were extracted to generate aluminum alloy keel members, and the generated aluminum profile keel members were classified and numbered according to different lengths and angles. The intersection of the members needs to be cut at an angle, and finally the six members are assembled into a hexagonal junction, and the joints are sealed. The design of the aluminum alloy keel rod also fully takes into account the problem of indoor condensate discharge, and the condensate collection and drainage groove is set up when the keel rod is opened, and the indoor condensate can be discharged through the drainage tank.

3.2 Spherical glass daylighting roof condensate drainage, variable angle glass sub-frame design

Due to the perennial humidity and large temperature difference of the project location, it is easy to form condensate on the glass in the glass sphere, and we also took into account the drainage problem of condensate when designing, when the water droplets are condensed on the glass, the water droplets will flow along the glass surface to the drainage groove of the aluminum alloy keel under the influence of gravity, and the drainage tank will discharge the condensate along the drainage groove after accumulation; The spherical glass lighting roof is composed of more than 1300 pieces of triangular glass of different sizes, the two glass panels have a certain angle at each other, and the angles of the triangular panels of different sizes are not the same, in order to solve the problem of many angles, we use the sub-frame of rotation and variable angle when designing the sub-frame, the sub-frame is composed of two parts of aluminum profiles, and is buckled together by the semi-circular buckle ring, which can be rotated to change the angle, and this design is adopted to solve the problem of many angles.

3.3 Spherical glass lighting roof aluminum alloy keel processing

The glass ball is a triangular panel, and the size is more, and there are many angles of the 6 aluminum profile members at the junction, which brings great difficulties to the processing and installation. Before the processing of the aluminum alloy keel member, the aluminum alloy keel is modeled according to the actual size and angle in the model, the members in the model are numbered respectively, and each number is extracted from the built model to generate a two-dimensional processing drawing, and the whole glass ball rod has more than 400 sizes and specifications, and more than 2,000 members.

3.4 Spherical glass lighting roof aluminum alloy keel installation

Spherical glass lighting roof aluminum alloy keel installation, first derive the keel positioning coordinates from the model, use angle steel to temporarily position the processed aluminum profile rods on the steel structure, weld the steel connector with the steel structure after adjusting it accurately, and install the connecting bolts of the steel parts and aluminum profile rods in time. The installation sequence is to install the vertical rods from bottom to top in a transverse circle first, and then install the vertical rods after the transverse installation is completed. After the installation of the whole rod is completed, the installation deviation of the rod can be checked with a total station to determine that the deviation does not affect the installation of the glass panel.

Name: Litong Glass

Mobile:+86 16632961602

Tel:+86 16632961602

Email:vip@litongglass.com

Add:Shahe city,Hebei,China